Page 91

106

Flame lost in MFEP

L

1. Check main valve wiring and operation -

correct any errors.

2. Check the fuel supply.

3. Check fuel pressure and repeat turndown

tests.

4. Check ignition transformer electrode, fl ame

detector, fl ame detector siting or fl ame rod

position.

5. If steps 1 through 4 are correct and the fault

persists, replace the module.

107

Flame lost early in run

L

108

Flame lost in run

L

109

Ignition failed

L

110

Ignition failure occurred

H

Hold time of recycle and hold option. Will not

be a lockout fault. Hold Only. Internal hardware

test. Not a lockout.

111

Flame current lower than weak

threshold (min fl ame current

0.8mA).

H

Hold time of recycle and hold option. Will not

be a lockout fault. Hold Only. Internal hardware

test. Not a lockout.

113

Flame circuit timeout

L

Flame sensed during Initiate or off cycle, hold

240 seconds, if present after 240 seconds,

system will lockout.

119

Control Interaction Fault

H

Flap valve identifi cations confi gured incorrectly.

122

Lightoff rate proving failed

L

1. Check wiring and correct any potential wiring

errors.

2. Check the VFDs (Variable-speed Fan Drive)

ability to change speeds.

3. Change the VFD

4. If the fault persists, replace the module.

123

Purge rate proving failed

L

128

Fan speed failed during prepurge

H or L

129

Fan speed failed during

preignition

H or L

130

Fan speed failed during ignition

H or L

131

Fan movement detected during

standby

H

132

Fan speed failed during run

H

137

ILK (Interlock) failed to close

H

1. Check wiring and correct any possible

shorts.

2. Check Interlock (ILK) switches to assure

proper function.

3. Verify voltage through the interlock string to

the interlock input with a voltmeter.

4. If steps 1-3 are correct and the fault persists,

replace the module.

149

Flame detected

H or L

Holds if fl ame detected during Safe Start check

up to Flame Establishing period.

150

Flame not detected

H

Sequence returns to standby and restarts

sequence at the beginning of Purge after the

HF switch opens if fl ame detected during Safe

Start check up to Flame Establishing period.

154

Purge Fan switch On

H or L

1. Purge fan switch is on when it should be off.

2. Check wiring and correct any errors.

3. Inspect the Purge Fan switch J6 terminal 3

and its connections. Make sure the switch

is working correctly and is not jumpered or

welded.

4. Reset and sequence the relay module.

5. If the fault persists, replace the relay module.

Code

Description

Lockout

or Hold

Procedure

N

EO

T

HERM

Commercial Boilers and Water Heaters

Содержание Neotherm NTH

Страница 4: ...LAARS Heating Systems...

Страница 36: ...Page 36 Figure 22 Hydronic Piping Single Boiler Zoning with Circulators LAARS Heating Systems...

Страница 52: ...Page 52 Figure 36 Ladder Diagram 7 H Ladder Diagram LAARS Heating Systems...

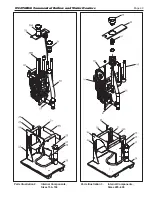

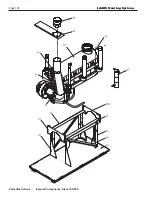

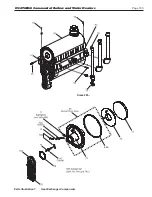

Страница 100: ...Page 100 Parts Illustration 4 Internal Components Sizes 750 850 LAARS Heating Systems...

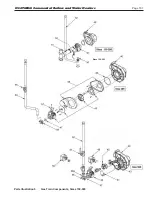

Страница 102: ...Page 102 Parts Illustration 6 Gas Train Components Sizes 600 850 LAARS Heating Systems...

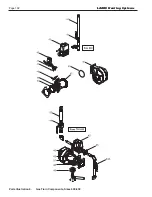

Страница 103: ...Page 103 Parts Illustration 7 Heat Exchanger Components 68A Sizes 285 NEOTHERM Commercial Boilers and Water Heaters...