Page 77

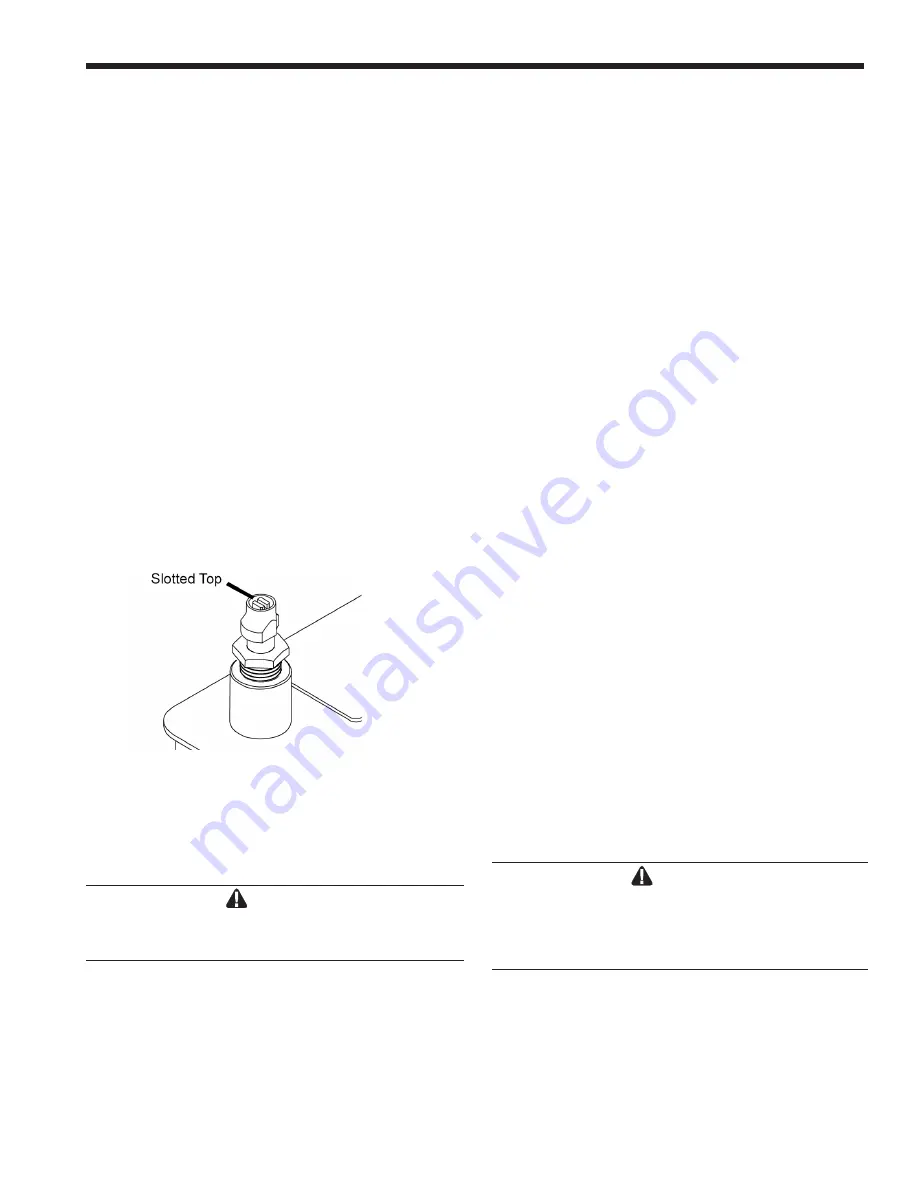

Figure 48. Air Vent

9. Shut down the entire system and vent all radiation

units and high points in the system piping, as

described in Step 4.

10. Close the make-up water valve and check

the strainer in the pressure reducing valve for

sediment or debris from the make-up water line.

Reopen the make-up water valve.

11. Check the gauge for correct water pressure and

also check the water level in the system. If the

height indicated above the boiler insures that water

is at the highest point in the circulating loop, then

the system is ready for operation.

12. Prime the condensate trap with water. (This is not

required for Boiler 600, 750, and 850 units.)

13. Refer to local codes and the make-up water valve

manufacturer’s instructions as to whether the

make-up water valve should be left open or closed.

14. After placing the unit in operation, the ignition

system safety shutoff device must be tested.

First, shut off the manual gas valve, and call

the unit for heat. The main gas terminals will be

energized, and attempt to light, for four seconds,

and then will de-energize. The unit will go into

lockout after the required number of trial for ignition

periods.

Next, turn the power Off, and then On again.

Press the manual reset button on the boiler control,

open the manual gas valve, and allow the unit to

light. While the unit is operating, close the manual

gas valve and ensure that power to the main gas

valve has been cut.

15. Within three days of start-up, recheck all air

bleeders and the expansion tank as described in

Step 4.

Important Note:

The installer is responsible for

identifying to the owner/operator the location of all

emergency shutoff devices.

WARNING

Do not use this appliance if any part has been under

water. Manufacturer requires boilers and water

heaters to be replaced, not repaired, if they have

been partially or completely submerged.

SECTION 9 FIRST START UP AND

ADJUSTMENT

9.A Filling the Boiler System

1. Ensure the system is fully connected. Close all

bleeding devices and open the make-up water

valve. Allow the system to fill slowly.

2. If a make-up water pump is employed, adjust the

pressure switch on the pumping system to provide

a minimum of 12 psi (81.8 kPa) at the highest

point in the heating loop.

3. If a water pressure regulator is provided on the

make-up water line, adjust the pressure regulator

to provide at least 12 psi (81.8 kPa) at the highest

point in the heating loop.

4. Open all of the bleeding devices on all radiation

units at the high points in the piping throughout

the system, unless automatic air bleeders are

provided at these points.

Note

- There is an air bleed (air vent with slotted

top) located on the left side of heat exchanger, on

top of the water manifold.

5. To remove all air from the heat exchanger, cycle

the boiler pump on and off 10 times, 10 seconds

on and 10 seconds off, . Then run the system and

appliance pumps for a minimum of 30 minutes with

the gas shut off.

WARNING

Failure to remove all air from the heat exchanger could

lead to property damage, severe injury or death.

6. Open all strainers in the circulating system, check

the operation of the flow switch (if equipped), and

check for debris. If any debris is present, clean it

out to ensure proper circulation.

7. Recheck all air bleeders as described in Step 4.

8. Start up the boiler according to the procedure listed

in this manual. Operate the entire system, including

the pump, boiler, and radiation units for one hour.

N

EO

T

HERM

Commercial Boilers and Water Heaters

Содержание Neotherm NTH

Страница 4: ...LAARS Heating Systems...

Страница 36: ...Page 36 Figure 22 Hydronic Piping Single Boiler Zoning with Circulators LAARS Heating Systems...

Страница 52: ...Page 52 Figure 36 Ladder Diagram 7 H Ladder Diagram LAARS Heating Systems...

Страница 100: ...Page 100 Parts Illustration 4 Internal Components Sizes 750 850 LAARS Heating Systems...

Страница 102: ...Page 102 Parts Illustration 6 Gas Train Components Sizes 600 850 LAARS Heating Systems...

Страница 103: ...Page 103 Parts Illustration 7 Heat Exchanger Components 68A Sizes 285 NEOTHERM Commercial Boilers and Water Heaters...