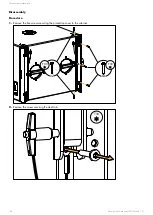

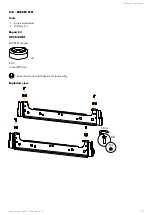

Corrective maintenance

D/R - BUMPER RIGGING PINS

Tools

• riveting pliers

Repair kit

For safety reasons, always use the new screws and spare parts provided in the KR.

If no new screws are available, use blue threadlocker.

KR PIN621

Kit 10 pins short round head screws & rivets

×20

×10

S142

621

M4×10 rivet

ball-locking pin Ø5/16" with lanyard

Exploded view

Kara owner's manual (EN) version 1.0

167

Содержание KARA

Страница 1: ...Kara owner s manual EN...

Страница 5: ...APPENDIX D Safety pin removal and insertion 199 APPENDIX E Recommendation for speaker cables 200 5...

Страница 148: ...Corrective maintenance 5 Secure the handle 5 mm 5 N m 148 Kara owner s manual EN version 1 0...

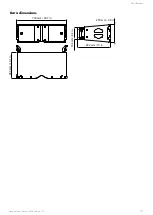

Страница 179: ...Speci cations SB18 dimensions 750 mm 29 5 in 707 mm 27 8 in 553 mm 21 8 in Kara owner s manual EN version 1 0 179...

Страница 181: ...Speci cations SB28 dimensions 700 mm 27 6 in 1300 mm 51 2 in 550 mm 21 7 in Kara owner s manual EN version 1 0 181...

Страница 201: ...L Acoustics 13 rue Levacher Cintrat 91460 Marcoussis France 33 1 69 63 69 63 info l acoustics com www l acoustics com...