53

PERIODIC SERVICE

C

Purging Procedures

Due to the effects air has on efficiency in hydrostatic drive

applications, it is critical that it is purged from the system.

Air creates inefficiency because its compression and

expansion rate is higher than that of the oil approved for

use in hydrostatic drive systems.

These purge procedures should be implemented any time

a hydrostatic system has been opened to facilitate

maintenance or the oil has been changed.

The resulting symptoms in hydrostatic systems may be:

1. Noisy operation.

2. Lack of power or drive after short term operation.

3. High operation temperature and excessive expansion

of oil.

Before starting, make sure the transaxle is at the proper

oil level. If it is not, fill to the specifications outlined in this

manual.

The following procedures are best performed with the

machine drive wheels off the ground. Then repeated

under normal operating conditions. If this is not possible,

then the procedure should be performed in an open area

free of any objects or bystanders.

1. Disengage the brake if activated.

2. With the bypass valve open and the engine running,

slowly move the motion control levers in both forward

and reverse directions (5 or 6 times).

3. With the bypass valve closed and the engine running,

slowly move the motion control levers in both forward

and reverse directions (5 to 6 times). Check the oil

level, and add oil as required after stopping the

engine.

4. It may be necessary to repeat Steps 2 and 3 until all

the air is completely purged from the system. When

the transaxle operates at normal noise levels and

moves smoothly forward and reverse at normal

speeds, then the transaxle is considered purged.

B

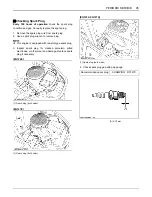

Changing Transaxle Fluid

(See "Replacing Transaxle Oil Filter Cartridge" in "EVERY

400 HOURS" in "PERIODIC SERVICE" section.)

EVERY 500 HOURS

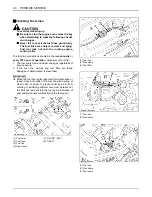

B

Electric Clutch Adjustment

The electric clutch serves two functions in the operation of

the mower. In addition to starting and stopping the power

flow to the cutter blades, the clutch also acts as a brake to

assist in stopping blade rotation when the PTO is switched

off or the operator presence control is interrupted.

When the clutch is disengaged, the air gap between the

armature and rotor must be adjusted to 0.04 mm for

proper operation. The air gap adjustment is made at three

bolts on the clutch. There are three inspection windows,

one next to each adjusting bolt. (See the figure below.)

1. Locate the inspection windows on the clutch.

2. Place a 0.04 mm feeler gauge in the slot between the

rotor and the armature. (See the figure.)

(1) Inspection window (x3)

(A) Electric clutch

Содержание ZG123S-AU

Страница 7: ......

Страница 12: ... 5 SAFE OPERATION 5 DANGER WARNING AND CAUTION LABELS ...

Страница 13: ...SAFE OPERATION 6 ...

Страница 14: ... 7 SAFE OPERATION ...

Страница 17: ...SERVICING OF MACHINE 2 1 Mower identification plate 2 Mower serial No 1 ROPS serial No ...

Страница 22: ...7 INSTRUMENT PANEL AND CONTROLS ILLUSTRATED CONTENTS 1 Anti scalp roller Front bolt shift type 22 ...