RADEX

®

-N

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

47110 EN

16 of 31

24

Please observe protection

note ISO 16016.

Drawn:

2019-07-23 Pz/Wb

Replacing:

KTR-N dated 2018-07-17

Verified:

2019-07-26 Pz

Replaced by:

Table 8: Tightening torques of clamping screws

Size

35

38

42

50

60

70

80

85

90

105

115

135

Clamping screws

M5

M6

M6

M8

M8

M8

M10

M12

M12

M12

M12

M16

Tightening torque T

A

[Nm]

8.5

14

14

35

35

35

69

120

120

120

120

295

!

Having started up the coupling the tightening torques of the screws have to be inspected

during the usual inspection intervals.

Disassembly:

STOP

Driving components falling down may cause injury to persons or damage on the machine.

Secure the driving components before disassembly.

•

Unscrew the clamping screws evenly one after another. During every revolution every screw may only be

unscrewed by half a turn. Unscrew all clamping screws by 3 - 4 pitches.

•

Remove the screws located next to the extraction threads and screw them into the respective extraction

threads until they fit.

•

The clamping ring is released by tightening the screws in the extraction threads evenly gradually and

crosswise.

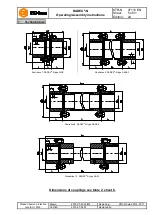

Illustration 19: Disassembly of clamping ring hub type 6.0

Illustration 20: Disassembly of clamping ring hub type 6.5

•

In case of a repeated assembly the hub bore and shaft have to be cleaned and afterwards lubricated with a

thin-bodied oil (e. g. Castrol 4 in 1 or Klüber Quietsch-Ex). The same applies for the taper surfaces of clamping

ring hub and clamping ring.

!

If these hints are not observed, the operation of the clamping ring hub may be affected.

4

Assembly

4.4 Assembly/disassembly of clamping ring hubs