RADEX

®

-N

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

47110 EN

14 of 31

24

Please observe protection

note ISO 16016.

Drawn:

2019-07-23 Pz/Wb

Replacing:

KTR-N dated 2018-07-17

Verified:

2019-07-26 Pz

Replaced by:

We recommend to inspect bores, shaft, keyway and feather key for dimensional accuracy

before assembly.

Heating the flange hubs lightly (approx. 80 °C) allows for an easier mounting onto the

shafts.

Please pay attention to the ignition risk in potentially explosive atmospheres!

STOP

Touching the heated hubs causes burns.

Please wear safety gloves.

!

With the assembly please make sure that the distance dimension E (see table 1 and 2) is

observed so that the coupling components are not in contact with each other during the

operation.

Disregarding this advice may cause damage to the coupling.

If used in potentially explosive atmospheres the setscrews to fasten the hubs as well as all

screw connections must be secured against working loose additionally, e. g. conglutinating

with Loctite (average strength).

For axial alignment of the coupling the distance dimension E (see table 1 and 2) is decisive. In order to adjust the

right dimension E you should proceed as follows:

•

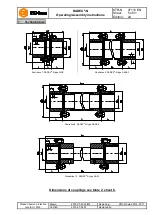

Mount the flange hubs on the shaft of driving and driven side (see illustration 17).

•

The internal sides of the flange hubs must be flush with the front sides of the shafts (see illustration 17).

•

Shift the power packs in axial direction until the distance dimension E is achieved (see table 1 or 2).

•

Fasten the flange hubs by tightening the setscrews DIN EN ISO 4029 with a cup point (tightening torque see

table 7).

Illustration 17: Assembly of flange hubs

Disassembly:

STOP

Driving components falling down may cause injury to persons or damage on the machine.

Secure the driving components before disassembly.

•

Release the setscrew in the hub and unscrew it by 2 - 3 pitches.

•

Pull the hub from the shaft.

4

Assembly

4.3 Assembly/disassembly of flange hubs