7 Servicing/Maintenance

48 of 72

Amarex N

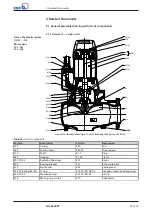

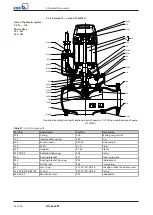

7.5 Reassembling the pump set

7.5.1 General information/Safety regulations

WARNING

Improper lifting/moving of heavy assemblies or components

Personal injury and damage to property!

▷

Use suitable transport devices, lifting equipment and lifting tackle to move

heavy assemblies or components.

CAUTION

Improper reassembly

Damage to the pump!

▷

Reassemble the pump (set) in accordance with the general rules of sound

engineering practice.

▷

Use original spare parts only.

NOTE

Before reassembling the motor section, check that all joints relevant to explosion

protection (flamepaths) are undamaged. Any components with damaged

flamepaths must be replaced. Refer to the "Flamepaths" annex for the position of

the flamepaths.

Sequence

Always reassemble the pump set in accordance with the corresponding general

assembly drawing.

Sealing elements

▪

O-rings

–

Check O-rings for any damage and replace by new O-rings, if required.

▪

Assembly adhesives

–

Avoid the use of assembly adhesives, if possible.

Tightening torques

For reassembly, tighten all screws and bolts as specified in this manual.

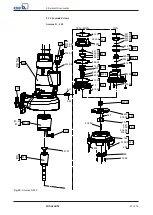

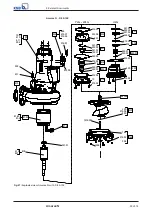

7.5.2 Reassembling the pump section

7.5.2.1 Installing the mechanical seal

Observe the following points to ensure trouble-free operation of the mechanical

seal:

▪

The shaft surface must be absolutely clean and undamaged.

▪

Immediately before installing the mechanical seal, wet the contact faces with a

drop of oil.

▪

For easier installation of the bellows-type mechanical seal, wet the inside

diameter of the bellows with soapy water (not oil).

▪

To prevent any damage to the rubber bellows, place a thin foil (of approximately

0.1 to 0.3 mm thickness) around the free shaft stub.

Slip the rotating assembly over the foil into its installation position.

Then remove the foil.

ü

The shaft and rolling element bearings have been properly fitted in the motor.

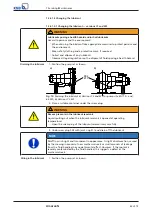

1.

Slide drive-end mechanical seal 433.01 onto shaft 210 and secure it with taper

lock ring 515 or circlip 932.03.

2.

Insert O-rings 412.04/412.35 and 412.15/412.11 into discharge cover 163, and

press them into bearing bracket 330 as far as they will go.

3.

Slide pump-end mechanical seal 433.02 onto shaft 210.

Содержание Amarex N

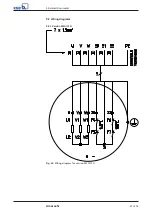

Страница 62: ...9 Related Documents 62 of 72 Amarex N 9 2 2 Version ULG Fig 33 Wiring diagram for version ULG...

Страница 70: ......

Страница 71: ......