Installation and operating instructions

IFC 020

12/1

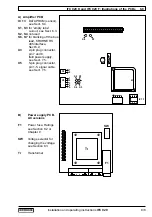

12 Block diagram – signal converter

1 Input amplifier

n

overdrive-proof signal processing,

rapid and accurate

n

digital signal processing and sequence

control

n

patented, high-resolution A/D converter,

digitally controlled and monitored

n

high signal-to-noise ratio through low-

loss field power supply

2 Field power supply

n

the low-loss field power supply

generates the pulsed, electronically

controlled DC current for the magnetic

coils of the primary head

n

the low-loss regulator reduces the power

take-off

n

high field current causes a high signal

level.

3 Current output

n

galvanically isolated from all other

groups

n

converts the digital output signal from the

µ

P 3 microprocessor into a proportional

current

n

HART

®

and RS 485-interfaces,

switchable

4 Binary outputs

n

galvanically isolated from other groups

n

selectable input/output combinations

n

pulse output, passive FET optocouplers

allow connection

of electronic and electromechanical

totalizers

n

status output, for limit value, error

identification, or flow direction

in forward/reverse flow mode (F/R)

5 Display/operator control unit

n

large-size illuminated LC display

n

3 keys for operator control of the signal

converter

n

connection to the internal IMoCom bus

6 IMoCom bus plug connector

n

for connection of external control and

test devices

7 External control input

(IFC 020 E only)

n

reset of internal totalizer

n

zero setting of all outputs

The standard

n

high accuracy

n

practice oriented standard equipment

n

current and pule output (galvanically

isolated)

n

status output, adjustable for many tasks:

indicators for trip point, flow direction and

errors.

n

IMoCom-Bus suitable for many in- and

external tasks

n

simple, uniform KROHNE control outline

n

very lowpower consumption

n

HART

®

and RS 485-interfaces