- 34 -

63

62

61

60

13

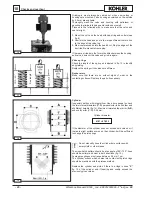

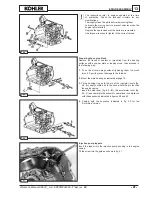

Camshaft

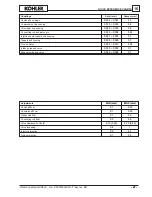

Insert the tappets into their housings on the casing. Mount the

camshaft, matching the reference marks on the gears (fig.60).

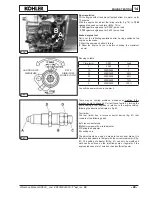

Play adjustment

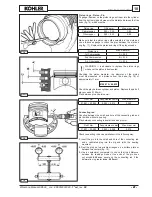

Crankshaft float:

Place a calibrated bar on the casing, on a level with the timing

system cover retention surface and use a thickness gauge to

check the distance between the gear and bar (fig. 61). Note

down the value measured.

Place a calibrated bar on the cover of the timing system, on

a level with the engine casing retention surface and use a

thickness gauge to check the distance between the bearing ring

and bar (fig. 62).

Note down the value measured.

The sum of the two measured values must be within:

0,10 ÷ 0,30 mm

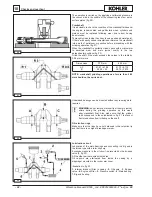

Camshaft float:

Place a calibrated bar on the casing, on a level with the timing

system retention cover and use a thickness gauge to check the

distance between the gear and bar (fig. 63). The value must be

between:

0,10 ÷ 0,25 mm

Engine assembly

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00

Содержание KD 500

Страница 1: ...KD 500 WORKSHOP MANUAL...

Страница 6: ...6 Index Workshop Manual KD500 _ cod ED0053029390 1 ed_rev 00...