- 28 -

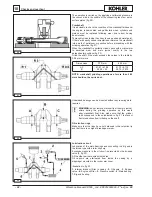

41

40

11

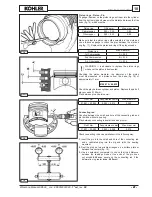

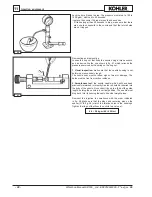

heck the time it takes to drop. The pressure must drop to 150 to

100 Kg/cm² withinn 6 to 40 seconds.

- replace the nozzle if it drops in less than 6 seconds.

- if it takes longer than 40 seconds to drop, make sure that there

are no carbon deposits in the nozzle and that the return holes

are not clogged.

Demounting and remounting

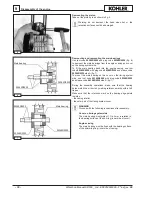

Loosen the ring nut that fixes the nozzle using a torque wrench

and as device like the one shown in fig. 41 which relieves the

pressure exercised by the spring on the ring nut.

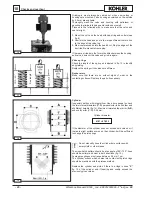

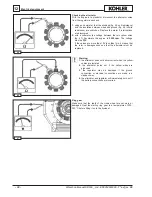

1. Visual inspection:

make sure that the needle housing is not

deformed or excessively rough.

The nozzle body must not show signs of wear or damage. The

holes must be free from carbon residues.

2. Smoothness test:

the nozzle needle, which will have been

previously immersed in impurity-free fuel, should be inserted into

the body of the nozzle. Noz extract it by up to a third of the guide

length, holding the nozzle in a vertical position. The needle must

drop back into its housing thanks to its actual weight alone.

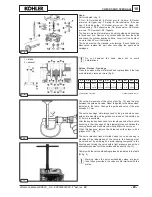

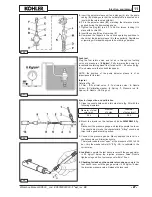

Remount the injection in compliance with the order indicated

in fig. 38. Make sure that the plugs and centering pins on the

spacer (N°

8

fig. 38) match the relative holes in the housings.

Tighten the ring nut that fixes the nozzle to a value of:

4,6 ÷ 5,6 kgm (45 ÷ 55 Nm)

Injection equipment

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00

Содержание KD 500

Страница 1: ...KD 500 WORKSHOP MANUAL...

Страница 6: ...6 Index Workshop Manual KD500 _ cod ED0053029390 1 ed_rev 00...