- 21 -

- 21 -

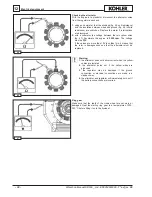

19

18

17

16

10

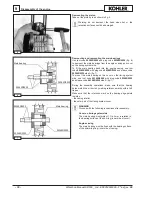

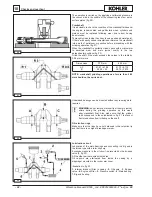

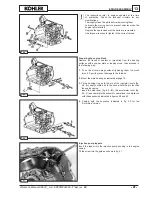

0,30 ÷ 0,50

0,80

0,25 ÷ 0,50

0,80

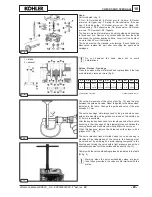

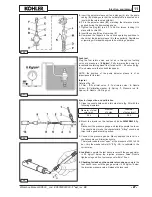

A = 0,22

B = 0,19

C = 0,16

21,997 ÷ 22,002

0,003 ÷ 0,013

0,040

21,997 ÷ 22,002

0,023 ÷ 0,038

0,070

Checks and overhaul

Piston rings - Piston - Pin

To gauge the wear on the piston rings, put them into the cylinder

from the bottom side and measure the distance between the free

ends (fig. 16), which must be:

Make sure that the piston rings slide smoothly in the slots and

use a thickness gauge to check the play between the slot and

ring (fig. 17). Replace the piston and rings if the play exceeds:

Piston ring

Fitting mm

Max. wear mm

Compression

Oil scrapper

WARNING: it is advisable to replace the piston rings

whenever the piston is demounted.

Checking the piston diameter: the diameter of the piston

must be measured at a distance from the base (fig. 18) of

approximately 11 mm.

Ø 86,915 ÷ 86,835

Check the play between cylinder and piston. Replace the parts if

play exceeds 0.150 mm.

Play between pin and piston mm:

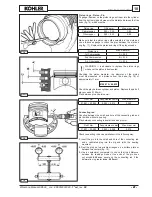

Piston ring

Max. wear mm

1st Compression

2nd Compression

3rd Oil scrapper

Pin Ø mm

Assy.clearance mm

Max. wear mm

Pin Ø mm

Assy.clearance mm

Max. wear mm

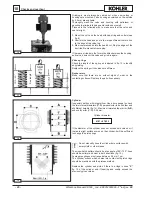

Connecting rod

Coupling between the small end hole of the connecting rod and

pin is made without a bearing.

Play between connecting rod small end and pin mm:

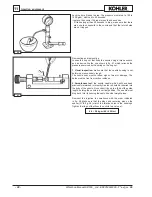

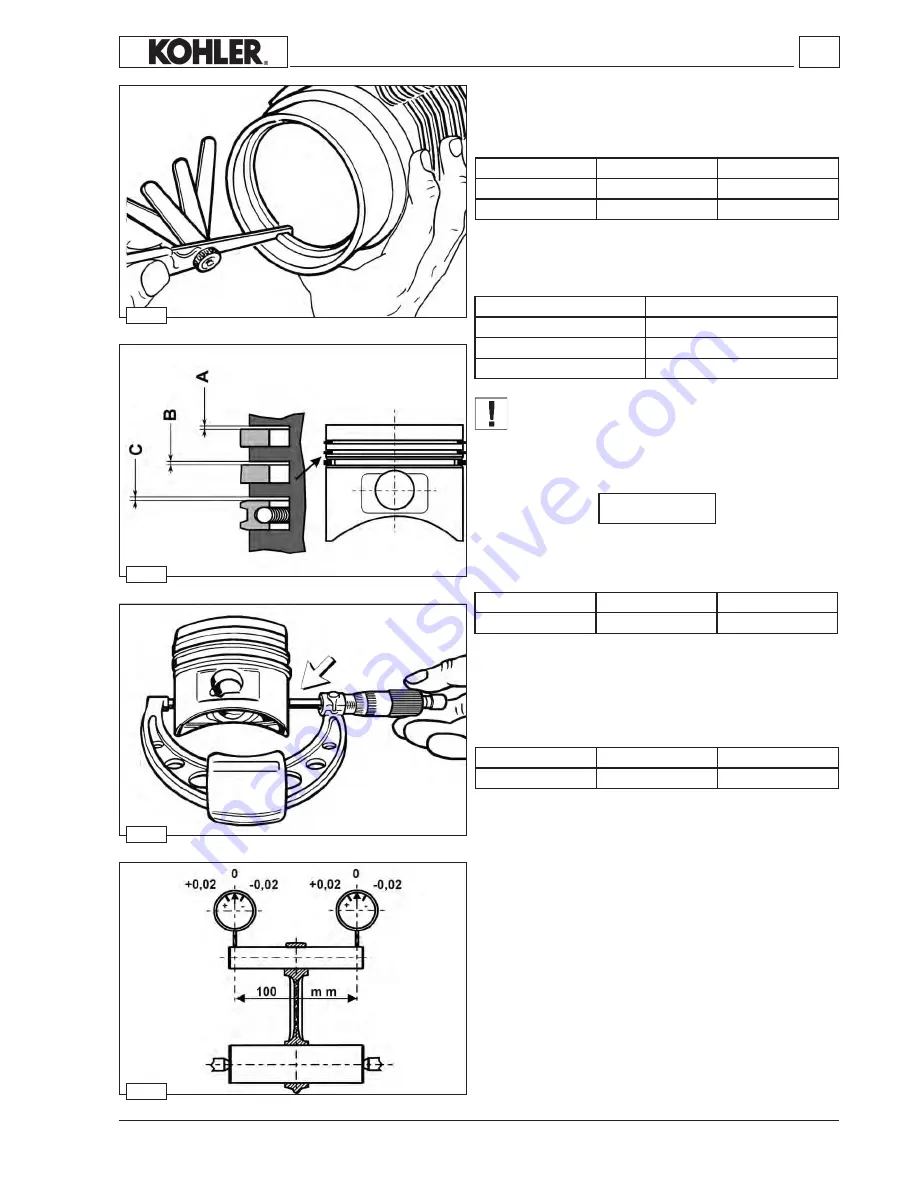

Check connecting rod axes parallelism in the following way:

1.

Insert the pin into the small end hole of the connecting rod

and a calibrated plug into the big end (with the bearing

mounted).

2.

Rest the plug on two prisms arranged on a surface plate or

between two centers (fig. 19).

3.

Use a centesimal comparator to check that the difference

between the readings made at the ends of the pin does

not exceed

0.02 mm

. square up the connecting rod if the

deformation is greater (

max. 0.05 mm

).

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00

Содержание KD 500

Страница 1: ...KD 500 WORKSHOP MANUAL...

Страница 6: ...6 Index Workshop Manual KD500 _ cod ED0053029390 1 ed_rev 00...