- 19 -

- 19 -

11

10

9

8

10

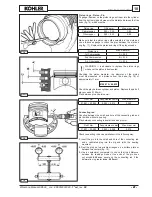

ØA

ØB

ØC1

ØC2

ØD1

ØD2

ØE(*) ØF1

ØF2

G

13

÷

13,01

13,025

÷

13,037

40,13

÷

40,145

35,13

÷

35,145

40

÷

40,025

35

÷

35,025

7

÷

7,01

6,96

÷

6,97

6,945

÷

6,995

0,8

÷

1

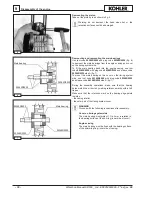

CHECKS AND OVERHAUL

Head

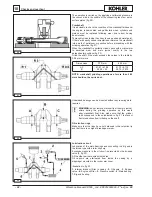

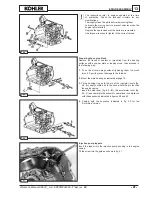

Parts indicated in fig. 8.

1.

Nut -

2.

Nut with ball -

3.

Rocker arm -

4.

Cotters -

5.

Rocker

arm stud -

6.

Upper cap -

7.

Spring -

8.

Air-relief valve -

9.

Lower

cap -

10.

Valve guide -

11.

Rocker arm cover -

12.

Head -

13.

Valve housing -

14.

Exhaust valve -

15.

Intake valve -

16.

Rocker

arm rod -

17.

Camshaft -

18.

Tappets.

The head is made of aluminium with valve guides and housings

in faced cast iron. Remove any carbon deposits from the head

and check the cylinder bearing surface. Level it off to a depth of

no more than 0.3 mm if deformed.

The head must not be cracked or deformed. If such faults are

discovered, replace the part after consulting the spare parts

catalogue.

Do not demount the head when hot to avoid

deformations.

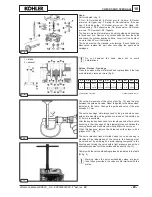

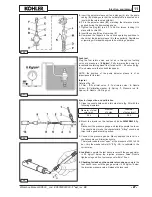

Valves - Guides - Housings

Clean the valves with a metal brush and replace them if the tops

are deformed, cracked or worn (fig. 9).

1 = intake

2 = exhaust

(*) with guide mounted.

measurements in mm

Check the dimensions of the valve stem (fig. 10) and the play

between the guide and valve. Ream the guide to the dimensions

indicated in the table. Change the guide and valve if the play

exceeds 0.1 mm.

The valve housings will always need to be ground when new

guides are mounted. Valve guides oversized on the outside by

0.10 mm are available.

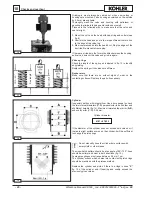

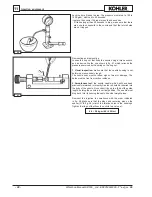

After the engine has been used for a lengthy period of time, valve

knocking in their housings at high temperatures will harden the

housing tracks and make manual milling difficult to carry out.

When this happens, remove the hardened surface layer with a

grinder at 45° (Fig. 11).

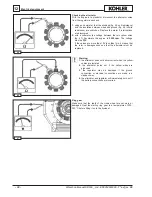

The valve retention track will widen when the valve housing is

machined. Final adaptation of the valve in the housing must

be carried out by smearing fine grain lapping compound in the

housing and turning the valve with a light pressure and with an

alternate movement until the surfaces bed perfectly (fig. 12).

Comply with the valve embedding values as indicated in the table

(

G

, fig. 9).

Warning: when the valve embedding values are lower

than those prescribed, the valves could interfere with the

piston.

Workshop Manual KD500 _ cod. ED0053029390 -

1° ed

_rev.

00

Содержание KD 500

Страница 1: ...KD 500 WORKSHOP MANUAL...

Страница 6: ...6 Index Workshop Manual KD500 _ cod ED0053029390 1 ed_rev 00...