6

2.

PRODUCT DESCRIPTION

The flow meter of the series KMT, based on the measurement principle of thermal mass flow, is suited for the

measurement of flow of air and gases in pipelines. Measurement of for instance the consumption of com-

pressed air, nitrogen, CO

2

, oxygen or other non-corrosive and non-flammable gases.

The KMT measures the volume flow at standard conditions according to DIN 1343 (P0 = 1023.25 mbar;

t0 = 273.15 K or 0 °C (32 °F). In addition to the standard volume flow, the measurand mass flow, norm flow

and temperature are available.

The KMT has an integrated consumption counter. The consumption quantity is indicated in the display and is

not lost after a power failure. Two signal outputs are available. Depending on the application, the outputs can

be configured as analogue (current or voltage), switch output or as pulse output for the measurement of the

consumption.

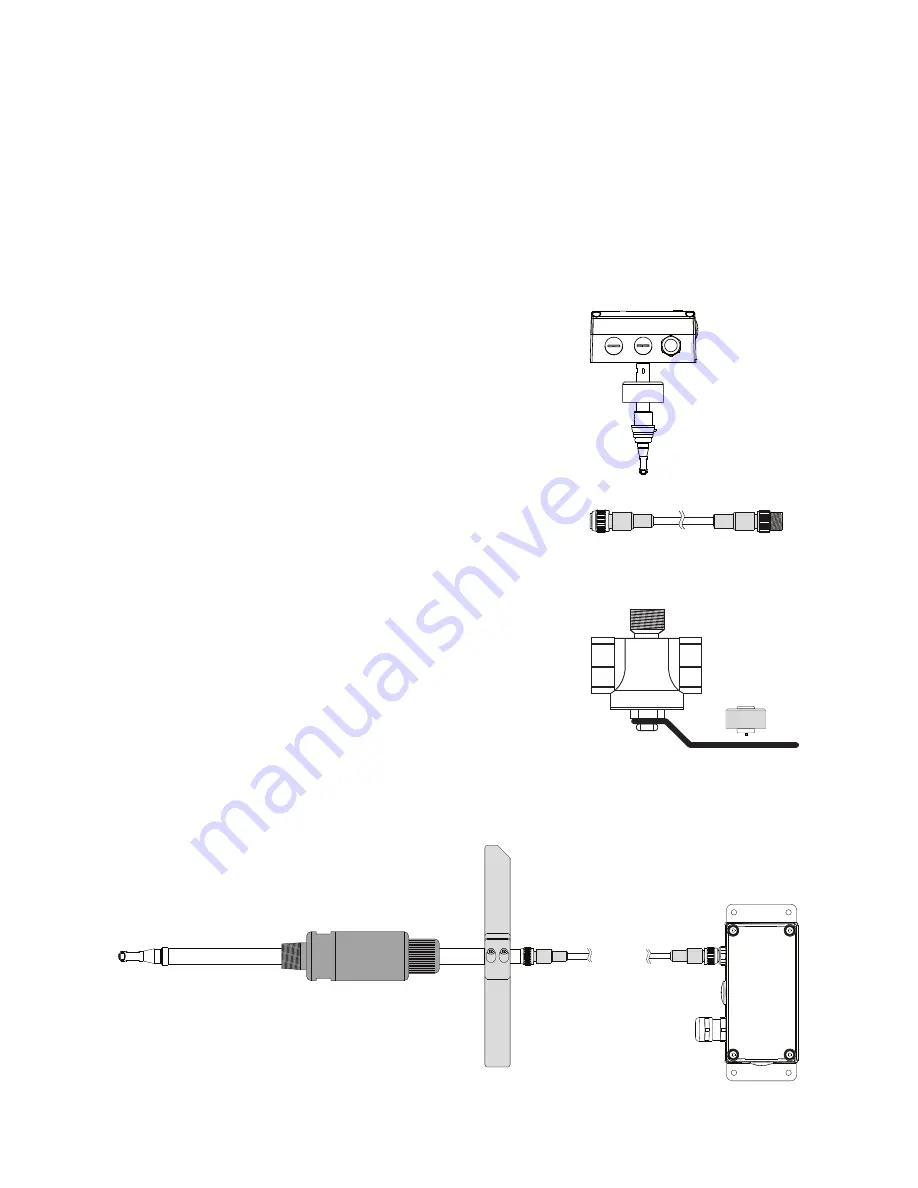

Measurement ball valve

The measurement ball valve allows for the easy and reliable installa-

tion within the pipeline. During installation in the pipeline, observe the

required inlet and outlet paths (see page 10). The nominal size of

the measurement ball valve must match the nominal size of the pipe.

The measurement valve with shut-off function allows for the instal-

ment and removal of the sensing probe with only interrupting the

process flow for a short moment. The measurment ball valve is suit-

able for pressures up to 16 bar (PN16) and available for pipe

diameters DN15 (1/2”) to DN50 (2”).

Signal conditioning with optional display

The enclosure with the signal conditioning is mounted either on the

measurement probe (model 1 or 2 compact) or is remote with a plug-

gable sensor cable up to 10 meter (33 feet) – (model 3 with remote

probe).

Sensing probe with measurement electronics

The interchangeable sensing probe contains the sensor element and

the measurement electronics, in which the data of the factory calibra-

tion is stored. The sensing probe is easy and quickly interchangeable

in the field, independent of the electronics for the signal conditioning.

After the exchange, the configuration of the outputs is unchanged.

Screw cap

The screw cap, with female thread, is screwed in place if the flow

meter is not installed and the pipeline has to be used.

Sensor cable (only by model 3 with remote sensing probe)

The sensor cable allows for the remote installation, up to 10 meter

(33 feet), of the sensing probe from the housing with the signal

conditioning.

1

5

3

4

2

1

2

3

5

4

KMT-1, KMT-2 and KMT-3

KMT-4

1

2

3

6

7

Содержание KMT-1

Страница 36: ...www kobold com...