24

10. TECHNICAL DATA KMT-4

Measuring value

Flow

Measurand

Volumetric flow at standard conditions acc. DIN 1343

P

0

= 1013.25 mbar

(14.7 PSI)

; t

0

= 0 °C

(32 °F)

Measuring range

0.2...100 Nm/s

(40...19685 SFPM)

or 0.2...200 Nm/s

(40...39370 SFPM)

Accuracy

in air at 9 bar (130.5 psi) (abs) and 23 °C (73 °F)

1)

± (1.5 % of measuring value + 0.8 % of full scale)

Temperature coefficient

± (0.1 % of measuring value / °C)

Pressure coefficient

2)

+ 0.5 % of measuring value / bar

Response time t

90

< 1 sec.

Sample rate

0.5 sec.

Temperature

Measuring range

-20...80 °C

(-4...176 °F)

Accuracy

at 20 °C (68 °F)

± 0.7 °C

(1.26 °F)

Outputs

Output signal and display ranges are freely scalable

Analogue output

voltage

0 - 10 V

max. 1 mA

current (3-wire) 0 - 20 mA and 4 - 20 mA R

L

<500 Ohm

Switching output

potential-free max. 44 VDC, 500 mA switching capacity

Pulse output

Totalizer, pulse length: 0.02...2 sec.

Digital interface

USB (for configuration)

Input

Optional pressure compensation

4 - 20 mA (2-wire; 15 V) for pressure sensor

General

Supply voltage

18 - 30 V AC/DC

Current consumption

max. 200 mA

Temperature range

ambient temperature:

-20...60 °C

(-4...140 °F)

medium temperature:

-20...80 °C

(-4...176 °F)

storage temperature:

-20...60 °C

(-4...140 °F)

Humidity working range

0...99 %RH no condensation

max. working pressure

16 bar

(232 psi)

Medium

compressed air or Non-Corrosive gases

Electrical connection

cable gland M16x1.5

Electromagnetic compatibility

EN61326-1

EN61326-2-3

Industrial Environment

Material

housing

metal (AlSi3Cu)

probe

stainless steel

sensor head

stainless steel / galss

non-return protection brass

Housing protection class

IP65 / Nema 4

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was

culated in accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) The flow meter is calibrated at 9 bar (abs) 130.5 psi. If the working pressure is different from 9 bar (130.5 psi) you can compensate the error by setting the actual pres-

sure with the configuration software.

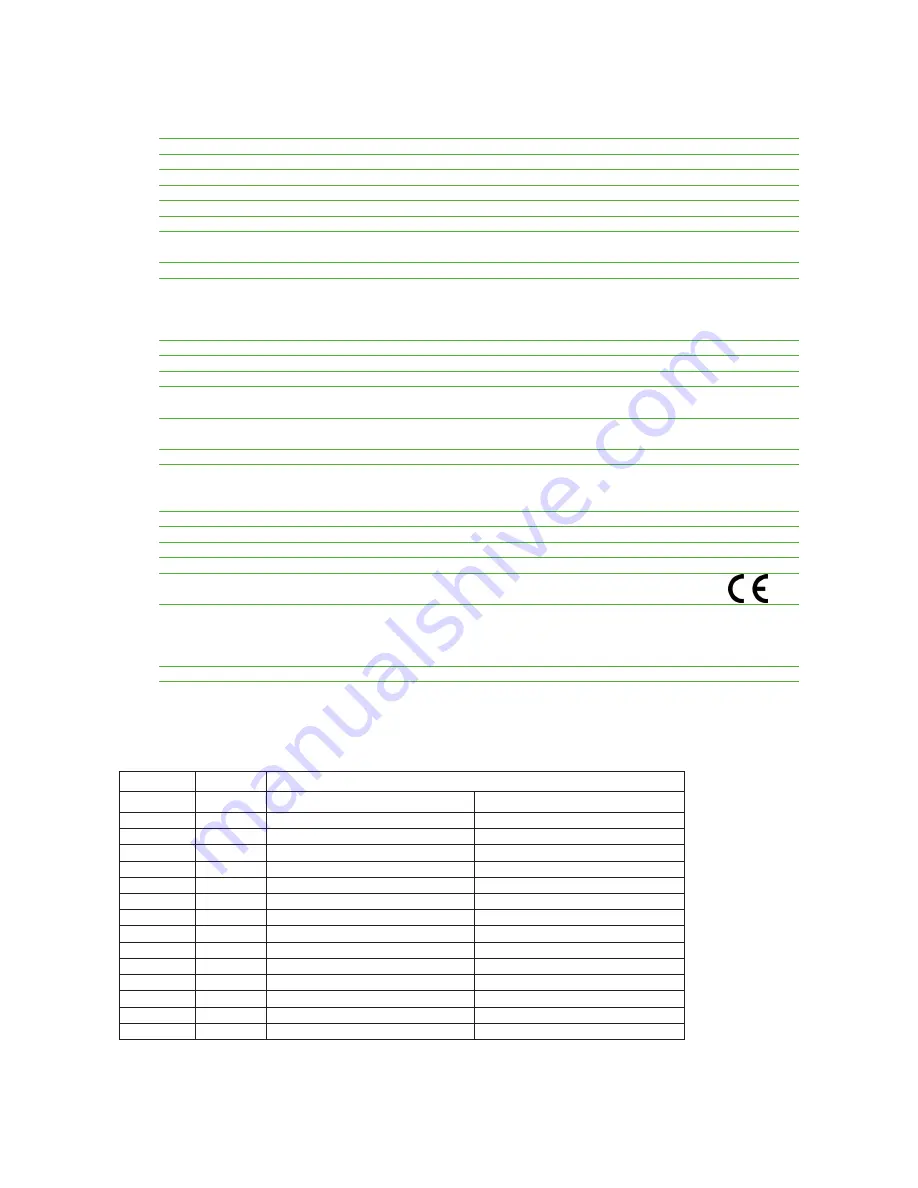

Flow measuring range in dependence on pipe diameter

pipe

inner Ø

measuring range

mm

(inch)

0.2...100 Nm/s

(40...19685 SFPM)

0.2...200 Nm/s

(40...39370 SFPM)

DN50 / 2“

54.5

(2.15“)

1.7...839 Nm

3

/h

1.0...493.8 SCFM

1.7...1679 Nm

3

/h

1.0...987.6 SCFM

DN65 / 2 1/2“ 70.3

(2.77“)

2.8...1397 Nm

3

/h

1.6...821.6 SCFM

2.8...2793 Nm

3

/h

1.6...1643.2 SCFM

DN80 / 3“

82.5

(3.25“)

3.8...1923 Nm

3

/h

2.3...1131.5 SCFM

3.8...3847 Nm

3

/h

2.3...2263.0 SCFM

DN100 / 4“

107.1

(4.22“)

6.5...3242 Nm

3

/h

3.8...1906.9 SCFM

6.5...6483 Nm

3

/h

3.8...3813.8 SCFM

DN125 / 5“

131.7

(5.19“)

9.8...4902 Nm

3

/h

5.8...2883.5 SCFM

9.8...9803 Nm

3

/h

5.8...5766.9 SCFM

DN150 / 6“

159.3

(6.27“)

14.3...7171 Nm

3

/h

8.4...4218.7 SCFM

14.3...14343 Nm

3

/h

8.4...8437.3 SCFM

DN200 / 8“

206.5

(8.13“)

24.1...12051 Nm

3

/h

14.2...7089.0 SCFM

24.1...24101 Nm

3

/h

14.2...14178.0 SCFM

DN250 / 10“ 260.4

(10.25“)

38.3...19163 Nm

3

/h

22.5...11272.6 SCFM

38.3...38325 Nm

3

/h

22.5...22545.3 SCFM

DN300 / 12“ 309.7

(12.19“)

54.2...27105 Nm

3

/h

31.9...15945.1 SCFM

54.2...54211 Nm

3

/h

31.9...31890.1 SCFM

DN350 / 14“ 339.6

(13.37“)

65.2...32591 Nm

3

/h

38.3...19172.5 SCFM

65.2...65183 Nm

3

/h

38.3...38345.0 SCFM

DN400 / 16“ 388.8

(15.31“)

85,4...42719 Nm

3

/h

50.3...25130.2 SCFM

85.4...85438 Nm

3

/h

50.3...50260.0 SCFM

DN500 / 20“ 486

(19.13“)

133,5...66749 Nm

3

/h

78,5...39266.0 SCFM

133.5...133498 Nm

3

/h

78,5...78531.9 SCFM

DN600 / 24“ 585

(23.03“)

193,4...96712 Nm

3

/h

113.8...56892.6 SCFM

193.4...193425 Nm

3

/h

113.8...113785.1 SCFM

DN700 / 28“ 682.6

(26.87“)

263,4...131675 Nm

3

/h

154.9...77459.8 SCFM

263.4...263350 Nm

3

/h

154.9...154919.6 SCFM

Содержание KMT-1

Страница 36: ...www kobold com...