41

E

nglish

MAINTENANCE CHECK LIST

DAILY

→

Check oil level. If oil levels are low, add compressor oil. Oil is available at the store where

you purchased the compressor.

→

Drain condensation from air receiver tank.

→

Check for any unusual noise or vibration.

→

Be sure all nuts and bolts are tight.

WEEKLY

→

Clean air filter by opening air filter cap.

→

Check oil level and fill up if necessary.

QUARTERLY

→

Change compressor oil and filter element.

→

Check safety valve.

→

Check pressure switch unloads to ensure compressor head unloads. whenever motor shuts

down.

→

Clean and blow off pump fins and motor.

→

Inspect air system for leaks by applying soapy water to all joints. Tighten joints if leakage is

observed.

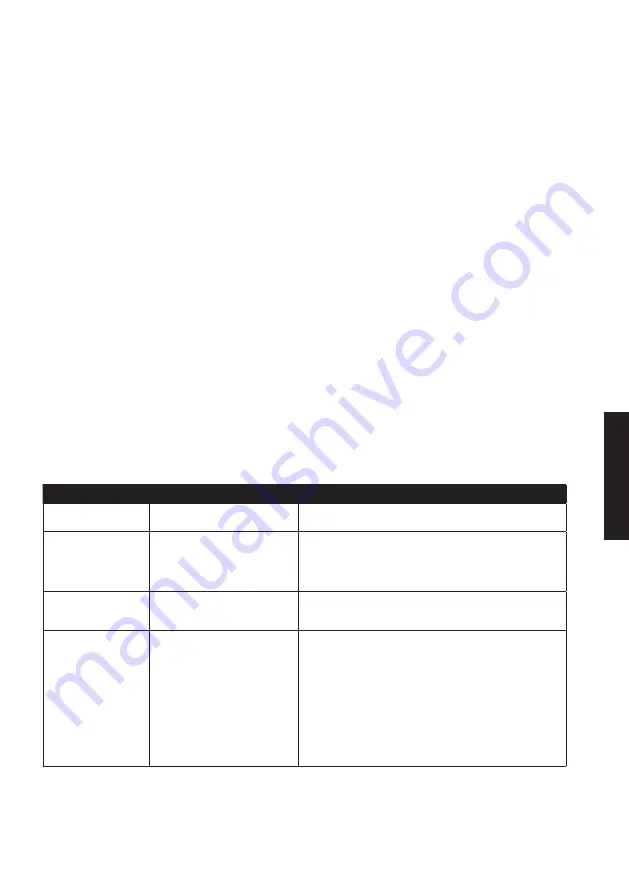

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Compressor will not

start

1. Loose electrical connection

2. Motor overheated

1. Check wiring connection

2. Press reset button or wait for automatic reset

Low pressure

1. Air leak in safety valve

2. Loose tube fittings

3. Restricted air filter

4. Defective check valve

1. Safety valve manually by pulling upward on the ring.

If condition persists, replace valve

2. Tighten fittings

3. Clean or replace

4. Replace safety valve

Safety valve releasing

on air receiver tank

1. Defect pressure switch or

improper adjustment

2. Defetive saftey valve

1. Check or proper adjustment and if problem persists, replace

pressure switch

2. Replace safety valve

Oil discharge and

excessive carbon for-

mation or appearance

of water an oil in the

air lines

1. Improper oil viscosity

2. Overfilling the crankcase

with oil

3. Restricted air intake filter

4. Carbon exhaust valves

5. Worn valves

6. Worn piston rings

7. High ambient temperature an/

or humidity

8. High percentage of running

time

1. Replace oil with SAE 10W-30 non-detergent

compressor oil

2. Drain oil and fill to proper level

3. Clean or replace filter

4. Clean or replace carbon exhaust valves

5. Replace valve assembly

6. Replace piston ring

7. Install a moisture separator and/or dryer

follow by and oil filter

8. Check for air leakage. If no leaks are found, you may require

an additonal compressor unit as your air

demand is too much for existing unit