34

35

www.klimor.com

www.klimor.com

MCKT - SUSPENDED MODULAR AIR CONDITIONING AND VENTILATION UNITS

OPERATION AND MAINTENANCE MANUAL

7.7 Heat Pump Module

First start-up of the system:

• Carry out wiring of the unit according to attached dia-

grams,

• Put the unit together and connect it to the system of air

ducts,

• Properly set the actuators on bypass damper and heat

exchanger damper

• Set the value in cross-flow h.e. pressure guage.

• Programme the variable frequency drives for the fans,

• Programme the variable frequency drive for the cooler

compressor,

• Select application depending on the type of heater,

• Adjust the unit’s airflow rate for the unit’s nominal per-

formance. The airflow rate both for intake and outlet has

to be within a range acceptable for a given unit. Stand-

ard airflow rate should be set with the counter-current

exchanger bypass damper closed. When adjusting the

unit’s airflow rate, the circuit breaker responsible for the

compressor’s operation should be disconnected.

• In case of reheater configuration, reduced airflow rate

should be set appropriate for the defrost mode. For

MCKT1-HPM it is 600 m

3

/h, while for MCKT2-HPM it is

1000 m

3

/h. Adjustment must be done with the coun-

ter-current exchanger bypass damper open. When

adjusting the unit’s airflow rate, the circuit breaker

responsible for the compressor’s operation should be

disconnected.

• Prior to first start-up of the cooling system one should

wait 3 h with switchgear power supply switched on and

fans switched off. This will allow the heating element of

the compressor casing to heat up the cooling oil appro-

priately.

• Switch on the compressor circuit breaker and start the

system. Move on to the screen displaying the pressure in

the cooling system. If after starting the compressor the

pumping pressure does not rise and the suction pres-

sure does not drop considerably, this may evidence that

the compressor’s power supply has not been connected

properly. Incorrectly connected phases cause the motor

to rotate in the wrong direction. After any two phases

have been swapped the compressor will work properly.

• The ratio of the amount of air at the intake to the amount

of air at the outlet must be within the range from 0.5 to 1.4.

• Following a correct test start, the assumed operation pa-

rameters may be set. The unit is fully ready for operation.

Detailed information concerning the above activities is

available in OMM re. control system.

7.8 Fan Section

Prior to start, it is necessary to make a thorough inspec-

tion of the fan section module. Make sure there are no

objects in the vicinity of the fan that could enter the

inside of the fan rotor.

Check if the rotor turns without resistance (e.g. adja-

cent elements scraping against one another).

Prior to starting the motor it is necessary to check:

• the motor’s power connection (the voltage of the power

supply network has to be the same as the voltage on the

motor’s nameplate,

• the condition of the earth wire between elements of the

fan section and the unit’s casing,

• the power cables inside the module must be firmly fixed

to the elements of the construction so as to prevent

them from getting close to movable elements (rotor),

• the direction of the rotor’s revolutions (to be checked by

impulse start of the motor) has to comply with the label-

ling on its casing. In case of non-compliance the direc-

tion of rotating supply power phases should be shifted

by swapping any two phases in the terminal box,

• setting of the inverters for fan start-up/warm-up time

(should be a minimum of 30 sec.).

In order for the rotor to be able to rotate freely, make

sure the slot between the rotor and the outlet nozzle

is appropriate.

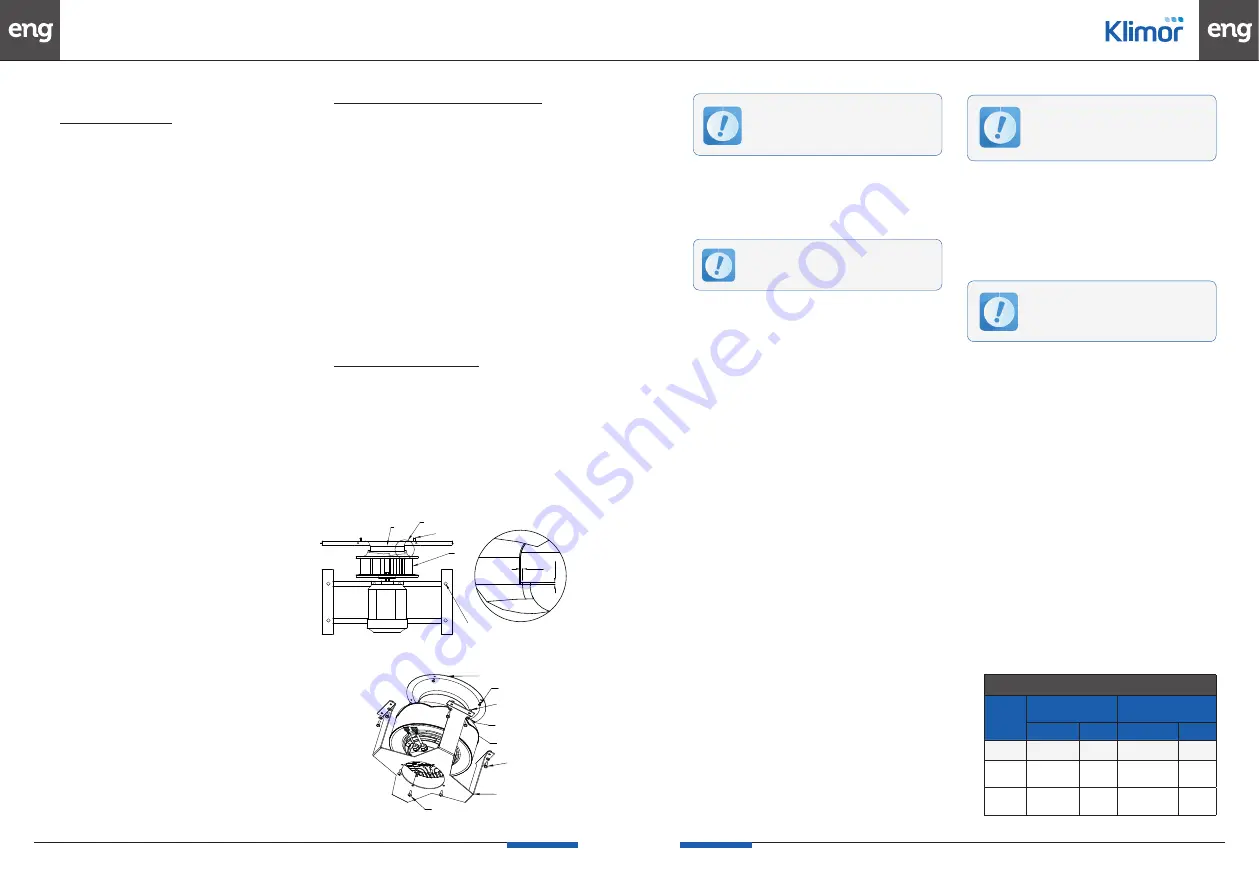

The slot can be adjusted as follows:

• loosen 6 bolts and move the outlet nozzle vertically,

• move the rotor horizontally together with the motor,

tray, load-bearing channel bars, vibration isolators, by

loosening 4 bolts.

The slot size should be about 2.5mm. The distance

the rotor is pulled onto the outlet nozzle should be

2.5mm.

The slot should always be checked following transport

of the device and its installation in the appropriate op-

erating position.

2,5

2,5

A

A

NOZZLE

ROTOR

NOZZLE POSITION

ADJUSTMENT BOLT

UNIT

POSITION

ADJUSTMENT

BOLT

DRAWING 19:

Adjustment of the slot between the rotor and outlet nozzle.

RIVET 4

BOLT M6x16

NOZZLE

FAN R3G

HANDLE

SCREW M6x16

BLINT RIVET NUT M6

SPRING WASHER

DRAWING 20:

Assembly of fan with EC motor

Continuous operation of the device with

the inspection panels off is prohibited.

Having made all the checks, the unit’s inspection panels

should be closed and the unit can be started up.

8. Start-up of the Unit

Only qualified assembly personnel may carry

out start-up operations.

The recommended time setting on the inverters for start-up/

warm-up of the fan is a minimum of 30s.

Start-up of the unit should be commenced with the adjustment

air damper shut at the inlet to the unit. Otherwise, with the air

damper wide open, the motor may be overloaded resulting in

durable damage. After the motor has been switched on, the

adjustment damper should be opened gradually, and the fol-

lowing parameters should be regularly monitored:

• the value of the intensity of the power consumed by the

motor,

• the amount of air pumped in the installation (airflow rate).

If the unit is fitted with an control system, the opening of

the air damper by the servomotor should be controlled. As

a rule, the intensity of the power consumed by the motor

should not be greater than the rated value, given the assumed

available amount of air and pressure.

When the fan is in operation, one should listen out for any wor-

rying, unnatural metallic noises or whether the unit’s vibrations

are not too heavy.

After 30 minutes the unit should be switched off and the follow-

ing fittings should be inspected:

• filters (if they have not been damaged),

• drip trays and traps (appropriate condensate drainage),

• fan section (temperature of motor and fan bearings –

also the slot between the nozzle and the fan rotor).

In units with secondary filters, start-up is recommended

without this filters cartridge installed. After start-up, it is

recommended to clean preliminary filters.

The antifreeze thermostat should be checked for correct op-

eration in temperature of air flowing into the water heater of

not much less than the thermostat setting – e.g. 1-2ºC. Then,

during operation of the unit the thermostat should be checked

for correct operation by shutting the inflow of heating water for

a moment.

Assessment of the correct operation of the MCKT unit and the

air conditioning and ventilation installation (system validation)

may be issued after careful adjustment of the operation param-

eters and after obtaining correct air parameters in the premises,

assumed by the design.

The above-mentioned check operations should be done before

the MCKT unit is commissioned.

When the MCKT unit is started up for the first

time, the Assembly and Start-up Report sho-

uld be filled in. The Report is in the form of an

annex to the Warranty and in p.14 of this OMM

9. Operation and Maintenance

The MCKT unit is designed for continuous operation. Peri-

odic overhauls of the unit are warranty required. Filters are

to be renewed by the user himself.

Operation and maintenance works have been present-

ed below.

Maintenance and servicing operations can

only be carried out when the unit is off and

not working.

9.1 Air Dampers

Air dampers, especially on the side of outside air, must

be kept clean. Excess contamination may cause the

blades to remain ajar or the rotating mechanisms to

seize.

Air dampers may be cleaned with an industrial vacu-

um cleaner with a soft suction nozzle, blown through

with compressed air or washed with water under

pressure and cleaning agents that do not cause alu-

minium corrosion.

9.2 Filters

MCKT units make use of G4 or M5 sectional filters

50mm in thickness as preliminary filters and M5÷F9

bag filters as secondary filters.

Filters should be renewed when the admissible pres-

sure drop on the filters has been exceeded (Table No.

6) or according to visual inspection. The unit must be

switched off during filter renewal. The class of new fil-

ters has to correspond to the class of the used filters.

During filter renewal also the filtration section has to

be cleaned.

Operation of the units is allowed only with the filters on.

Table No. 7

Filter Dimensions

MCKT FILTER DIMENSIONS AND SIZES

Unit Size

G4/M5 Preliminary

Cassete Filter

M5÷F9

Secondary Bag Filter

W x H

Amount

W x H

Amount

MCKT01

610x305

1

592x287

1

MCKT02

915x305

1

592x287

287x287

1

MCKT03

915x425

1

592x407

287x407

1