24

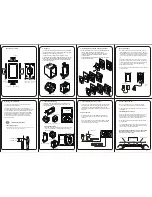

Solar System Installation Guide

Copper Piping

Copper piping should be sweated with lead-free solder. For large installations, silver solder is required.

Insulation

All pipe work on the solar loop should be insulated with high temperature insulation. High temperature insulation is

essential as regular pipe insulation will melt at temperatures experienced by solar pipes.

The R value of the insulation should be at least R2.6. The only pipes which should not be insulated are the pipes to the

expansion tank as they should allow heat to dissipate when the system is experiencing excessive heat and pressure. The

last five feet of the cold water feed should be insulated as well. A shut off valve is required for the cold water supply to

the tank.

Pipe Supports

All piping between the storage tank and collector should be supported at a maximum ten feet (10’) on vertical pipes and

six feet (6’) on horizontal runs. The supporting straps must not crimp the pipe insulation. Pipes should be sloped at a

minimum of ¼” per foot to insure proper system draining.

Roof Penetrations

All roof penetrations required for plumbing or wiring should be properly sealed with the correct flashings for the roof

type according to applicable codes and to the standards of the National Roofing Contractors Association.

If using copper pipe, it is best to use high temperature roof jacks to get the piping through the roof. The best connection

method has one penetration on each side of the collector. All outside piping must be insulated with UV resistant

insulation.

If using the flexible stainless steel piping, the roof penetrations are a bit more difficult. Refer to local codes for exact

requirements for your area. It is often desirable to use a section of PVC piping for the tubing to come through. This

makes sealing with the roof jack much easier than if the tubing were to be passed through by itself. A single roof

penetration in the middle, at one end, or one at each side of the collector is acceptable.

Solar Controller

All electrical aspects of the installation should be undertaken by a qualified electrician. Note that for safety, the pump

and sensor connections should always be wired prior to connecting power to the solar control panel.

Important: The solar control panel must have a permanent electrical power supply which must not be interrupted

either manually or with a time switch. If the permanent electrical supply to the building is to be switched off for any

period of time, the solar collector(s) should either be covered, or the system drained and the tubes removed.

In order to protect the normal operation of the control panel, it should be located at least 4” from insulated pipes which

may become hot during operation.

The controllers use PT1000 temperature sensors containing twin core 20 gage copper wire and are 5 feet in length.

Sensor cables can be extended with twin core copper cable of 20 gage up to 164 ft and 16 gage between 164 – 328 ft.

Screened cable should be used on the sensor cables to prevent RFI from electrical cables. All wires should be rated for at

least 220°F. All connections to extend the cables should be housed in a junction box for protection.

The following wiring diagram is of a basic domestic hot water application (System 1). It shows the power supply

connection, the sensor inputs T1 & T2 and output connection to the pump R1.