The operator must then initiate the

parked regeneration. This results in the compressor being un‐

loaded and the engine can start the regeneration. The process requires approximately 20 to 30 mi‐

nutes and, during this time, the engine can autonomously adjust its speed to arrive at the optimal

operating point for the regeneration.

Because the regeneration will start only at temperatures above 660 °F, it is recommended to

warm up the engine in LOAD before initiating

parked regeneration.

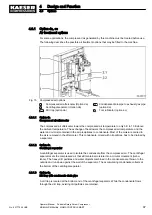

4.8 Sealed floor pan

The machine is fitted with a sealed floor pan catching liquids in the event of leaks.

The drain points for compressor cooling oil and engine coolant are led to a central point outside.

The sealed floor pan:

■ Cannot catch all liquids contained in the machine, but is intended only to capture small

leaks in the vicinity of endangered components.

■ is fitted with de-watering lines closed with plugs. These lines must be tightly re-closed af‐

ter performing any cleaning work.

■ Is equipped with service openings which are closed with bungs. These openings must be

tightly re-closed after performing any cleaning work.

When other components are removed from the sealed floor pan, (for example the sheet metal

cover) they must be properly re-sealed prior to installation.

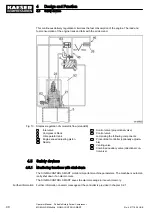

Position of service openings in the closed floor pan:

Fig. 14 Position of service openings in the closed floor pan

1

Coolant oil drain - oil separator tank - com‐

pressor

2

Airend/oil cooler, coolant oil drain point

3

Engine oil drain

4

Draining line

5

Cleaning opening closed with bung

4.9 Options

The options available for your machine are described below.

4

Design and Function

4.8

Sealed floor pan

46

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M58utility SIGMA CONTROL SMART

No.: 901779 08 USE