JOHNSON CONTROLS

14

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

SECTION 2 - OPERATION

the RSR compressor and oil separator will have to

be changed when changing from other refrigerants to

R-134a and when chang ing back from R-134a to other

refrigerants.

See the

SECTION 4 - MAINTENANCE PROCE-

of this manual for the correct procedure for

adding and removing oil from the RSR unit compres-

sor and oil separator.

Check Oil Level in Vacuum Pump (Low Pressure

Units)

The oil level in the vacuum pump should be at the mid-

point of the oil level window.

Unlike the high pressure units, the oil in the vacuum

pump is not the same as that used in the refrigeration

unit being serviced. A special vacuum pump oil must

be used.

Vacuum pumps are tested with DuoSeal® brand oil

and shipped with a full charge to prevent unnecessary

contamin ation. The oil acts both as a lubricant and the

vacuum seal between the rotating components. An

additional supply of oil is furnished with each pump

with instructions to drain and discard the oil, when it

becomes contaminated, and replace with the fresh oil.

DuoSeal oil has been especially prepared and is ideally

suited for use in vacuum pumps be cause of its desir-

able viscosity, low vapor pressure and chemical stabil-

ity. The vacuum guarantee on all pumps applies only

when Duoseal oil is used.

Oil Contamination

The most common cause of a loss in efficiency in a

vacuum pump is contamination of oil. It is caused by

condensation of vapors and by foreign particles. The

undesirable conden sate emulsifies with the oil which

is recirculated and sub jected to re-evaporation during

the normal cycle of pump activity thus reducing the

ultimate vacuum attainable. Some foreign particles and

vapors may form sludges with the oil, impair sealing

and lubrication and cause eventual seizure. Periodic oil

changes are necessary to maintain efficient opera tion

of the system. The required frequency of changes will

vary with the particular system. Experience with the

pro cess will help you determine the normal period of

operation before an oil change is required.

See

SECTION 4 - MAINTENANCE PROCEDURES

for Low Pressure Units for the correct procedure to add

or remove oil from the vacuum pump and oil separator.

Filter Dryer Replacement Element

The RSR unit contains a filter dryer that removes

moisture, acids, as well as solid particles from the re-

frigerant that is being recovered. The filter dryer con-

tains a removable element (Sporlan #RC 4864) that

must be in place before the unit is used.

The filter/dryer element must also be changed when:

1. Changing the type of refrigerant being recov-

ered.

2. When the liquid sight glass indicator shows that

excessive moisture is in the refrigerant.

3. After recovering refrigerant from a refrigeration

unit that has had a motor burnout.

4. After the RSR unit has been run for 100 hours.

If the refrigeration unit, from which the refrigerant

is being recovered, has experienced a hermetic com-

pressor motor burn out, or if the liquid sight glass/

moisture indicator shows excessive moisture in the

refrigerant, a filter/dryer (Sporlan C-415) should be

inserted at the end of the RSR liquid re frigerant hose ,

where it connects to the refrigeration unit liquid con-

nection.

Before the refrigeration unit is re charged, the valve

at the end of the liquid hose and on the refrigeration

unit (at the opposite end of the filter dryer) should be

closed. Remove the fllter dryer and re place it with a

new filter dryer with the arrow pointing in the direc-

tion of the re frigeration unit.

The arrow indicating direction of flow

should point toward the RSR unit when

liquid refrigerant moves from the refrig

eration unit to the RSR storage vessel.

See

SECTION 4 - MAINTENANCE PROCEDURES

for specific instructions for changing the filter/dryer

element.

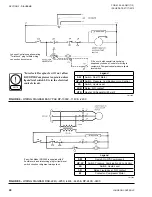

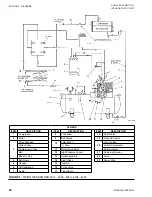

Connecting Hoses

The refrigerant hoses, furnished with the RSR unit,

are con nected to the evaporator and condenser of the

refrigeration. unit as shown in the schematic diagram

. A third hose, used

with the portable unit only, is connected between the

valve on the top of the storage vessel and the refriger-

ant connection on the condenser of the portable RSR

unit.

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...