JOHNSON CONTROLS

45

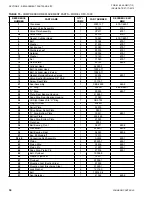

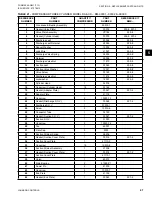

SECTION 5 - REPLACEMENT PARTS AND KITS

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

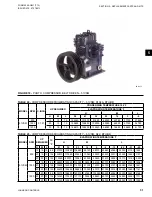

5

REFERENCE

NUMBER

PART NAME

QUANTITY

PART

NUMBER

48

Pressure Rls. Tube Number 2

1

41-1005

49

Steel Ball 3/8 Dia.

1

4-40-1200

50

Pressure Release Valve

1

41-0992

51

Hex Hd. Cap Screw, 5/16 – 18 x 1/4

6

2-01-0320

52

Pressure Rls. Tube Number 1

1

41-0986

53

Sheet Metal Screw Number 6 x 1/4

3

2-03-3104

54

Thrust Disk

1

41-1766

55

End Cap

1

41-0672

*Oil Case Assembly (61-417D) includes oil case, drain valve and level window.

REPAIRING OIL LEAKS

Location, Cause and Effect

Oil leaks may develop wherever two mating faces are

sealed with a gasket. Such seams may fail as the result

of deterioration of the gasket material, loosening of the

screws caused by temperature variations, or improper

care as the result of previous reassembly. Typical gas-

keted seams in a vacuum pump are located at the shaft

seal and the mating faces of such mechanical surfaces

as the suction chamber cover, the oil case, and the dis-

charge chamber cover. The importance of a gasketed

seam is determined principally by its function. If it is

a vacuum seal, the ultimate performance of the pump

is dependent upon it. If it is an oil seal, the pump may

be operated satisfactorily for some time without loss of

function. Eventually, of course, a great loss of oil may

cause harmful damage.

Repairing Technique

Thin composition gaskets are generally used for large

irregu larly shaped areas. A replacement joint of this

type should be thoroughly cleaned of all previous gas-

ket material and the mating surfaces cleaned of any

nicks.

REPAIRING VACUUM LEAKS

Good vacuum seals are an essential and important at-

tribute of a vacuum pump. A good seal is dependent

upon the quality of the mating surfaces as well as the

sealant and its preparation. The mating faces should be

carefully inspected for any projections or foreign par-

ticles which might interfere with proper mating. Slight

projections such as nicks and burrs are most easily re-

moved by rubbing with a fine abrasive stone. The sur-

face of the mating parts may be washed with a solvent

or alcohol after which they must be thoroughly dried.

TABLE 22

- VACUUM PUMP REPLACEMENT PARTS – MODEL CRR-1 (CONT'D)

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

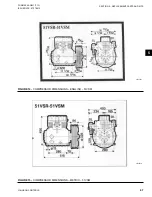

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...