JOHNSON CONTROLS

29

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

4

GENERAL

Replacement of Filter Dryer Element

1. Unplug the RSR power cord.

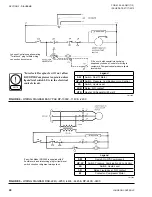

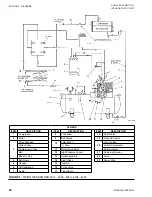

2. Close valves 1, 2, 3 and 4 in the manifold (See

charge valve.

3. Remember that the system is under pressure and

safety glasses and gloves should be worn during

this operation.

4. Slowly turn each of the bolts, holding the end

plate on the canister, open one or two turns. Al-

low the reduc tion of pressure within the canister

before completely removing the end plate.

5.

Remove the old filter core from the canister and

remove the “O” ring gasket from the end plate.

Wipe the in side of the canister and the end plate

clean with a clean cloth.

6. Replace the “O” ring gasket with a new one after

wip ing it with a coating of the same type of oil

being used in the compressor.

7.

Remove the new filter/dryer element (Sporlan #

RC 4864) from the hermetically sealed wrapper.

The new element must be placed in the canis-

ter immediately since it would otherwise absorb

moisture from the sur rounding air.

8. Replace the end plate and bolt in place using an

alter nate pattern for tightening the bolts.

9. Prior to opening the compressor discharge valve,

crack valve number 3 of the manifold and slightly

break the flare connection in the tubing where it

enters the com pressor discharge. Allow the air to

be purged from the filter dryer and then tighten

the flare fitting and open the compressor discharge

valve.

Belts

The Refrigerant Recovery/Recyle Unit (RSR) com-

pressor drive belt should be checked frequently for

excessive wear and tightness. If belt is in bad condition,

it should be replaced immediately. Correct belt tension

pre vents the motor pulley from slipping, keeping the

transfer unit operating at peak efficiency.

The belt tension adjustment should be made so the belt

is taut, but not too taut to create excessive bearing loads.

Due to the pulsating load created by the compressor, the

belt tension must be greater than for a normal steady

load. Belt tension can be accurately determined with the

use of a belt tension gauge which gives a direct reading

of belt load as determined by the deflection. A tension

of 100 Ibs. is considered to be the normal belt tension.

After 36 to 48 hours of operating time, the belt should

stretch to a normal operating point and a further check

for proper tension should be made. Good alignment and

belt tension are important to insure long belt life, quiet

opera tion and to maintain top system performance.

Pulley Alignment

A very important factor in compressor operation is cor-

rect pulley alignment. The compressor pulley must be

in perfect alignment with the motor pulley and it is im-

portant that the shaft key is in place on the shaft and the

pulley bolt drawn tight, when installing a pulley. The

pulley alignment may be checked by holding a 1/2”

rod –2 or 3 feet long – firmly in the V groove of the

compressor drive pulley wheel and making sure the rod

falls squarely in the motor pulley grooves. A further

check may be made by seeing that the belt, as it goes

from pulley to pulley, comes off the pulley grooves

perfectly straight and that there are no side-way bends

in the belt, as it approaches or leaves the pulleys. Pul-

leys and belts must be clean and free of oil.

Adding or Changing Oil (High Pressure Units)

When the RSR is not running and the refrigerant pres-

sures have equalized, the oil should be 1/2 to 3/4 of the

height of the sight glass in the compressor oil sump.

To add oil:

1. Unplug the power cord.

2. Close the compressor discharge and suction

valves and manifold valves 1 and 4 (See

) and vent the pres sure from the

compressor. Using an oil pump, open the drain

valve on the compressor sump, and pump oil into

the compressor until it is at the proper level.

3. The type of oil should be the same as that used in

the refrigeration unit being serviced.

SECTION 4 - MAINTENANCE PROCEDURES

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

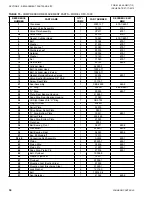

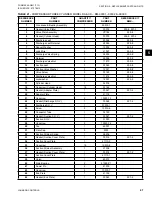

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...