JOHNSON CONTROLS

32

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

SECTION 4 - MAINTENANCE PROCEDURES

Installation of Seal Assembly

1. Check all surfaces to make certain nicks and burrs

do not exist.

2. Wash all parts of the seal assembly in clean oil of

the same type being used in refrigeration unit be-

ing serviced.

3. Push the seal assembly onto the shaft. Move the

seal assembly in and out on the shaft to ensure a

good seal.

4.

Place a very light film of oil on the matching met

-

al faces where the “O” ring is to be placed. Place

the “O” ring in the groove.

5. Place the seal retainer plate in position with the pol-

ished surface facing the compressor. Turn the bolts

in evenly while rotating the shaft, making sure that

the clearance between the shaft and the hole in the

retainer plate is the same all around the circumfer-

ence. If clearance is not the same all around, gently

tap the seal retainer plate until it is so. Tighten bolts

diagonally opposite to the required torque (See

Servicing Valve Plate and Head

In removing the head, extra care should be taken not to

damage the sealing surfaces.

Removal of Head and Valve

(See

1. Remove the four bolts (15) from cylinder head.

The four bolts removed are longer in

length than the remaining head bolts.

2. Remove the remaining bolts in the cylinder head

and remove the valve plate (3), and cylinder head

from the crankcase by tapping lightly under the

ears which ex tend from the valve plate. If the head

and valve plate adhere, hold the head and tap the

valve plate ears away from the head with a soft

hammer. Do not hit or tap the head to separate the

head and valve plate because damage to the head

may result.

3. All gasket material adhering to the head, valve

plate, or cylinder, should be carefully removed in

such a manner that the machined sealing surfaces

are not scratched or nicked.

Installation of Head and Valve Plate

1.

Apply a thin film of clean

YORK Refrigeration

oil on the area of the crankcase to be covered by

the cylinder gasket. Place the cylinder gasket in

position on the cylinder so the dowel pins in the

crankcase go through the dowel pin holes in the

cylinder gasket.

2.

Apply a thin film of clean Y

ORK Refrigeration

oil to the top and bottom valve plate area to be

covered by gas kets. Place the valve plate in posi-

tion on the cylinder gasket so the discharge valve

assemblies (i.e. the smaller diameter assemblies

with the retainer over the valve reed) are facing up

and the locating dowel pins go through the dowel

pin holes in the valve plate.

3. Place the head gasket (4) in position on the valve

plate (3) so the dowel pins go through the dowel

pin holes in the gasket.

4.

Apply a light film of clean

YORK Refrigeration

oil on the machined surface of the cylinder head

which matches the head gasket. Place the head on

the cylinder head gasket so the dowel pins go into

the dowel pin holes in the head.

5.

Apply a thin film of clean

YORK Refrigeration

oil to the service valve flanges on the head and on

the service valve flange. Place a service valve gas

-

ket in position on the cylinder head service valve

flanges. Place the service valve in position on the

proper service valve ports and insert the longer

bolts through the service valve mount ing pads, the

head, end valve plate and in the crankcase.

6. Insert the remaining head bolts and run in all the

bolts so the bolt heads make contact. Tighten the

head and service valve bolts to the required torque,

by tightening the service bolts first. Then tighten

the remaining in a sequence so bolts diagonally op-

posite each other are evenly drawn to the specified

torque.

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

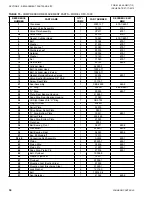

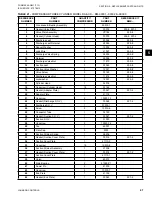

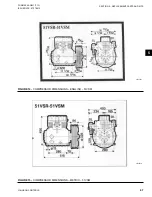

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...