JOHNSON CONTROLS

35

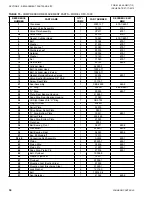

SECTION 5 - REPLACEMENT PARTS AND KITS

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

5

TABLE 16 -

COMPRESSOR TORQUE SPECIFICA-

TIONS – MODEL CFC-1000

DESCRIPTION

CAPSCREWS AND BOLTS

THREAD

SIZE

TORQUE

STD.

(FT. LBS)

METRIC

(KM)

Rod Cap Screw

1/4-20

7-8

0.96–1.1

Valve Plate Screw

1/4-28

6

0.82

Oil Filler Plug

1/8 NPT

10–15

1.38–2.0

Bearing Retainer

1/4-28

6–7

0.82–0.96

Seal Retainer Plate

10-32

54–78

0.62–0.89

Cylinder Head

5/16-24

24–28

3.3–3.8

Flywheel Capscrew

5/16-24

24–28

3.3–3.8

Mounting Foot

3/8-16

15–20

2.0–2.7

Rotolock Valve

—

30–40

4.1–5.5

Oil Sight Glass

1 1/8-18

UNEF

75

10.4

TABLE 17 -

COMPRESSOR PISTON SELECTIVE

FITS

SELECTIVE FITS

CLEARANCE

INCHES

MM

Piston Pin to Piston

.0002/.0003

.005/.007

Piston Pin to Rod

.0002/.0003

.005/.007

Piston to Cylinder

.0032/.0042

.081/.106

Rod to Shaft Journal

.0007/.0015

.018/.038

COMPRESSOR REPLACEMENT

If the compressor fails and it is evident that the crank-

shaft bearings, connecting rods or pistons have been

damaged, the entire compressor should be replaced.

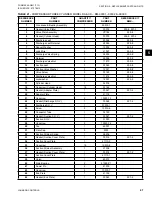

TWIN CYLINDER MODEL CFC1000

Compressor Rotation: Either Clockwise or Counter-

clockwise.

Listed on

are the part numbers

and part names for each component in our belt-driven

compressor Model CFC 1000. These part numbers and

part names are indexed by reference numbers as shown

in

which shows the layout of

each part.

Please note that BMK-(number) refers to a replace-

ment kit of parts as follows:

BMK683-7

Gasket Kit

BMK679-1

Valve Plate Kit

BMK665-8

Seal Kit

BMK680-6

Crankshaft and Bearing Kit

BMK695-1

Piston and Rod Kit (Standard)

BMK695-2

Piston and Rod Kit (.020 Oversize)

BMK679-3

Valve Plate Kit (Cad & Nickel Plated)

Components in the valve plate kit, seal kit, piston and

rod kit and the crankshaft kit are shown within an area

enclosed by a line on the drawing on

COMPRESSOR MODEL 16799 (RST-2240,

RSR-2250 & RP-2400)

Shaft Seal Assembly Servicing

When servicing the shaft seal, extreme care must be

taken when removing or installing the parts to prevent

damage to the lapped surfaces and other seal parts. The

portion of the shaft upon which the seal fits must be

free of scratches, burrs and dirt, and the seal housing

cavity must be clean.

Removal Of Seal Assembly

1. Remove the sheave and key from the shaft.

2. Remove the seal retainer plate bolts and gently re-

move the seal plate.

3. Remove the seal assembly from the shaft.

4. Clean all parts to be reused.

Installation Of Seal Assembly

1. Check all surfaces to make certain nicks and burrs

do not exist.

2. Wash all parts of the seal assembly in clean YORK

Refrig eration Oil.

3. Oil shaft with refrigeration oil to allow new seal to

be pushed into position.

4. Put on spring holder and spring. Be sure that

spring is centered in spring holder.

5. Slide the assembly along shaft just far enough to

center in spring and hold spring in place. Do not

compress the spring at this stage.

6. Before putting on end plate, thoroughly clean and

oil with 300 viscosity refrigeration oil on both seal-

ing faces. Install floating seats in end plate as fol

-

lows:

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...