JOHNSON CONTROLS

39

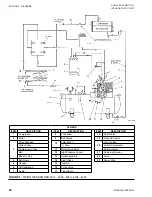

SECTION 5 - REPLACEMENT PARTS AND KITS

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

5

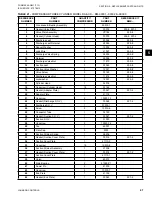

REFERENCE

NUMBER

PART

NAME

NUMBER

REQUIRED

PART

NUMBER

38

Seal End Plate Gasket

1

16720

39

Seal End Plate

1

16721

40

Head Pipe Plug 1/8”

3

16036

41

Half Union Elbow

1

16037

42

Flare Cap 1/4”

1

16730

43

Service Valve, Compressor Suction 7/8S.

2

16737

Service Valve, Compressor Discharge 7/8S.

1

16737

44

Dowel Pins

8

16034

Front Bushing - Crankcase

1

16733**

Rear Bushing - Crankcase

1

16734**

Complete Gasket Set

1

16816

Discharge Manifold Crossover Tube Assembly

1

16815

* Part cannot be ordered separately. Must be ordered as complete

Assembly.

** Must be line bored and reamed after pressing into crankcase.

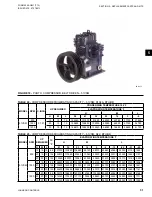

All parts used in Model D799 same as Model 16799 except for the following:

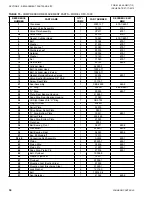

TABLE 20 -

MODEL D799 COMPRESSOR PARTS (OLD STYLE)

DETAIL

NUMBER

PART

NAME

NUMBER

REQUIRED

PART

NO.

1

Crankcase (includes front & rear bushing)

1

16900

2

Cylinder

2

16902

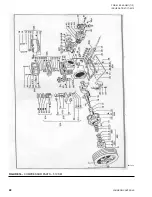

Changing the Valve Plate Assembly

(See

Figure 10 on page 37 and Figure 11 on page

1. Remove cylinder head bolts, cylinder head and

valve plate assembly from compressor.

2. Remove all traces of gasket material from both

the cylinder and the cylinder head flanges.

3. Thoroughly clean the cylinder head using a good

solvent as a cleaning agent.

4. Thoroughly clean the top of the pistons and the

cyl inder flange: The most efficient manner in

which to accomplish this is to bring one piston

flush with the top of the cylinder and clean the

top of the piston and approximately one-half of

the cylinder flange in one operation. This process

should be repeated for each cylinder using a good

solvent as a cleaning agent.

Do not allow any solvent to seep into

crank case oil.

TABLE 19

- COMPRESSOR REPLACEMENT PARTS – DISCONTINUED MODEL 16799 (CONT'D)

5. Place the valve plate gasket on the cylinder head

fol lowing the outline of the cylinder head itself to

insure correct gasket position. Use a thin film of

refrigerant oil to make gasket adhere to cylinder

head.

6.

Place the cylinder gasket on the cylinder flange

using a thin film of refrigerant oil to make gasket

adhere to the cylinder flange.

7. Thoroughly clean the valve plate assembly with a

good solvent.

8. Place suction reeds on the cylinder dowel pins.

9. Place the valve plate assembly on the cylinder us-

ing the cylinder dowel pins as a guide.

10. Replace the cylinder head (on which the valve

plate gasket has already been placed—See No. 4

above) and make certain the dicharge outlet is op-

posite the suction port on the cylinder.

11. Replace cylinder head and tighten belts, using the

torque requirement specified for the valve plate

(See

.

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

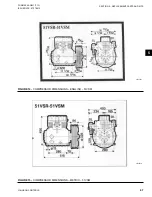

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...