JOHNSON CONTROLS

15

SECTION 2 - OPERATION

FORM 50.40-OM1 (713)

ISSUE DATE: 07/17/2013

2

Only the dedicated storage vessel and interconnecting

hose set supplied with the RSR unit can be used for the

hookup.

Use of Unspecified Equipment Could

Result in Personal Injury and Release of

Refrig erant to the Atmosphere.

When using the Portable Recovery Pak, it is manda-

tory that the EasyTank™, manufactured by Johnson

Controls, be used as the storage vessel. These contain

the proper pressure relief valves, liquid level float

switch and matching intercon necting wiring for the

safety switches. In order for the Por table Recovery Pak

to operate, the interconnecting safety wiring must be

plugged into the matching socket.

Shipping Charge

When the unit is shipped from the factory, a holding

charge of dry nitrogen is placed in the storage vessel

under a pres sure of approximately 5 psig. Prior to first

using the RSR unit, the pressure should be relieved to

the atmosphere and the vessel evacuated with a vacuum

pump to a vacuum of 29 inches of mercury. Evacuate

using gas connection (con nection between valves 1 &

2), open valves 1, 2, 3, & 4 during evacuation – close

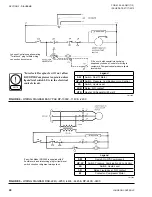

valve 5. (See

FIGURE 1 -

YORK RSR SYSTEM FLOW DIAGRAM

LD01105

OPERATION OF REFRIGERANT STORAGE/

RECYCLE SYSTEM

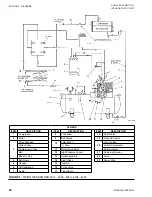

Liquid Transfer – Refrigeration Unit to RSR

Storage Vehicle

This method is recommended for the initial phase of

refrig erant recovery. (See

To bleed air from the connecting liquid refrigerant

hose:

1. With valve 5 closed, crack valve 6 at the evapora-

tor.

2. Slowly open refrigerant hose connection at 5 until

a very small amount of refrigerant exists at the

hose connection. (Make sure unit is above 0 psig

– if not, do not use this step.)

3.

Retighten hose fitting at valve 5.

To bleed air from the remaining refrigerant hose:

1. Close valves 1 and 2.

2. Crack valve 7.

3. Bleed refrigerant from hose con nection at mani-

fold and retighten hose fitting as above. (Make

sure unit is above 0 psig – if not, do not use this

step.)

Содержание YORK EASYTANK LD17584

Страница 4: ...JOHNSON CONTROLS 4 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...JOHNSON CONTROLS 28 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 48: ...JOHNSON CONTROLS 48 FORM 50 40 OM1 713 ISSUE DATE 07 17 2013 LD17572 Figure 16 COMPRESSOR PARTS 51VSM ...