VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

S100-200 IOM (MAY 08)

Page 20

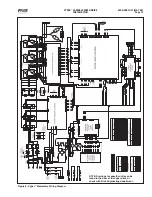

EXTERNAL POWER AND CONTROL WIRING

External power and control signals must be brought in and

out of the Vyper

™

variable speed drive. The unit requires the

wiring to be properly installed to supply power to the unit for

processing. The Vyper

™

also outputs processed power to the

motor of a compressor package. The two connection points

are at the following locations:

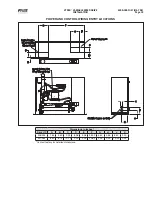

INPUT POWER CONNECTION

For Remote-mounted units,

the Input power junction is located on the upper left side of

the cabinet. This location provides a junction for three power

cables, T1, T2, and T3. Incoming Power leads (See Figure

11) must have their ends stripped of insulation for insertion

in the junction area.

Be sure there is no power running

through the leads during installation!

The external power leads may be inserted into the top of the

circuit breaker and then fastened via a hex style wrench (See

Figure 12). In addition the grounding connection is adjacent

to the external power connections and located on the top of

the left wall of the cabinet. (See Figure 13)

Input Power Lead Torque Requirement

Wire Size

Material

Torque

4-4/0

Cu

275 in-lb

Figure 11 - Insulation stripped from power leads

OUTPUT POWER CONNECTION (Remote Mount)

The wire

leads from the motor must be prepared prior to installation.

The preparation involves stripping lead insulation for the mo-

tor to expose the copper wire within the lead.

NOTE: About

½" to 1" of exposed wire is recommended.

Before working on the motor wir-

ing, be certain that the Drive has

been powered down for at least fi ve

minutes. This allows the internal capacitors/resistors to

discharge the DC bus and allow for safe maintenance

of the unit. Failure to do so may cause serious injury

or death. Also ensure that all power has been removed

from the leads while connecting to the Vyper

™

.

The motor leads must be brought in from the top of the unit.

Carefully remove the panel, which covers the motor lead entry

point, by removing the screws. Wires may then be run into

the interior of the cabinet. Be sure to leave enough relief in

the leads so no undue stresses are transferred to the motor

connection location in the interior of the unit. The attachment

points are T1, T2, and T3. They are labeled in the body of

the cabinet at the motor lead attachment points. Insert the

stripped connectors and tighten with a small wrench. Con-

nectors should not loosen when given a moderate tug by

hand.

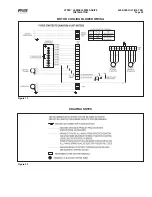

Figure 12 - Fastening the power lead

Figure 13 - Grounding Lug

For remote-mounted units it is required that a dV/dt “snub-

ber” fi lter be installed between the Vyper

™

and the motor

to ensure a clean power signal into the motor. This fi lter is

required for all remote-mounted systems with power leads

between 3-50 feet in length.

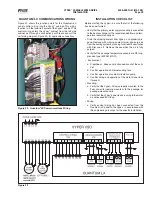

OUTPUT POWER CONNECTION (Package Mount)

Package-mounted Vyper

™

drives have a different output

confi guration than the remote-mount Vyper

™

. The Package-

mounted Vyper

™

uses 3/8" terminal lugs for the output power

connection to the compressor motor. Appropriate motor lead

hardware should be used to make the connections. The at-

tachment lugs are labeled T1, T2, and T3 and are located on

the back right wall of the interior of the Vyper

™

cabinet (See

Figure 14). The power wiring emerges from the rectangular

Содержание Frick vyper VYA PG -46

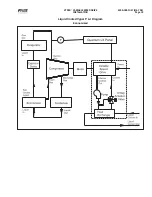

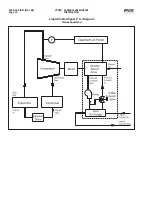

Страница 15: ...VYPER VARIABLE SPEED DRIVE INSTALLATION S100 200 IOM MAY 08 Page 15 Liquid Cooled Vyper P I Diagram Economized ...

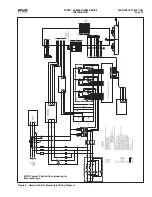

Страница 24: ...VYPER VARIABLE SPEED DRIVE INSTALLATION S100 200 IOM MAY 08 Page 24 ANALOG BOARD WIRING Figure 21 ...

Страница 62: ...S100 200 IOM MAY 08 Page 62 VYPER VARIABLE SPEED DRIVE NOTES ...

Страница 63: ...S100 200 IOM MAY 08 Page 63 VYPER VARIABLE SPEED DRIVE NOTES ...