Start the machine cautiously.

Reduction of noise exposure:

Exposure to high levels of noise can damage your hearing.

The shape of the tool and the speed significantly influence the

generation of noise.

Use tools with a largely closed body of revolution.

Avoid unnecessarily high speeds.

Only work with well-sharpened tools.

Use suitable hearing protection.

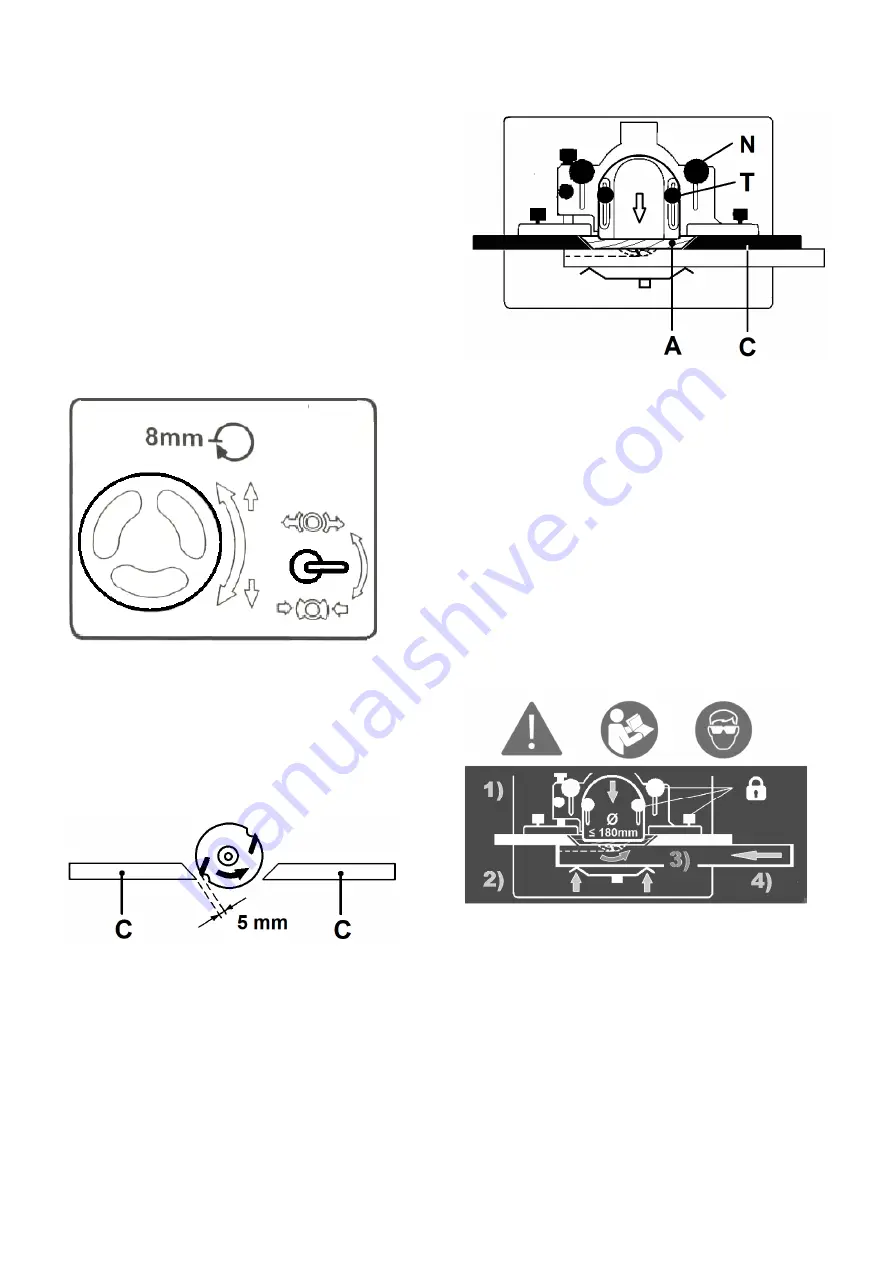

7.5 Spindle vertical travel

After you loosen the clamping lever the spindle height can be

adjusted with the hand wheel. One revolution corresponds to

a travel of 8mm (2mm for each ¼ turn)

Fig 18.3

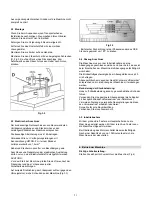

7.6 Shaper fence installation

Install the shaper fence body first. To do so, screw the two

bolts (N, Fig 19.2) into the tapped holes in the machine table.

Set the fence boards (C, Fig 19.1) approx. 5mm close to the

cutter rotation.

Fig 19.1

Use the spacer board (A, Fig 19.2) to securely guide small

gibs.

Fig 19.2

The spacer board is clampled between the fence boards (C).

The spacer board is a wear part and a new board needs to be

fabricated if the clearance around the cutter becomes too big.

Have a scrap workpiece available to allow proper positioning

of the fence and the shaper guard.

Adjust the shaper guard to guide the workpiece and to protect

from accidental cutter contact.

The shaper guard is fastened to the fence cover and can be

opened for tooling and setup access.

Connect the fence to a dust collector.

Before starting work, check manually that the cutter rotates

freely and that fence and guard are correctly clamped.

Before starting the machine; slide the fence cover forward

and clamp it with 2 lock knobs (T, Fig. 19.2), bring the shaper

guard (hold downs) into working position (Fig. 19.3).

Fig 19.3

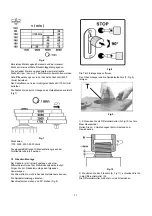

7.7 Curved guard installation

The curved guard (Fig 20) supplied with the machine can be

mounted to the machine table and allows a maximum tool

diameter of 150mm.

Содержание JWS-34KX

Страница 44: ...A 1 A 2 A 3 A 4 A 5 ...