Attention:

The sanding spindle may only be operated at the lowest

(1700 RPM) spindle speed.

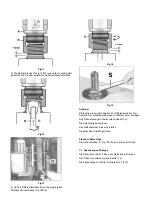

Before starting work, check manually that the sanding spindle

rotates freely and that all components are correctly clamped.

Feed the workpiece straight across the machine table, holding

your fingers close together, guiding the workpiece with the

palm of your hands.

Always keep your hands well clear of the rotating sanding

drum.

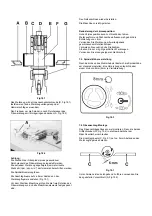

7.9 Tenoning carriage installation

The optionally available tenoning carriage can be placed on

the machine table and is guided in the T-groove.

The wood press (C, Fig 25) and the mitre gauge profile (E)

assure the stability of the workpiece.

Fig 25

The covers (D) must be adjusted into proximity of the

workpiece and locked in place.

- workpiece height max 100mm

- workpiece width max 120mm

Adjust the shaper fence to suit the tool diameter used.

The shaper guard (B) should be positioned above the tool.

The vertical press (A) can be lifted to its maximum.

Before starting work, check manually that the cutter rotates

freely and that all components are correctly clamped.

Feed the workpiece by sliding the carriage towards the tool

with both hands pressing the workpiece onto the mitre gauge

profile (E).

Always keep your hands well clear of the rotating cutting tool.

Note:

Tenoning work requires power and torque.

In most cases 3500 RPM will perform best.

8. Maintenance and inspection

General notes:

Maintenance and inspection work may only be carried out

after the machine is protected against accidental starting

by pulling the mains plug.

Clean the machine regularly.

Inspect the proper function of the dust extraction daily.

Defective safety devices must be replaced immediately.

All protective and safety devices must be re-attached

immediately after completed cleaning, maintenance and

inspection work.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.

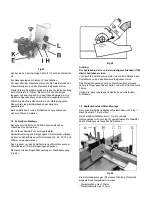

Drive Belt:

The belt tension must be inspected regularly.

Motor Break:

The motor break works electro-mechanically (break motor).

If breaking time should exceed 10 seconds, the motor break

assembly needs to be replaced (JET Stock Nr.: JWS34-BME).

Contact your Jet service station immediately.

9. Trouble shooting

Motor doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or power cord-

consult an electrician.

*Overload has reacted-

wait 10 min and start again.

*Spindle lock is engaged.

Cutter doesn’t come to speed

*Too big or heavy a tool-

choose smaller spindle speed.

*Extension cord too light or too long-use adequate power

supply.

*V-belt excessively tensioned-

apply proper tension.

Wrong spindle direction

*3-phase sequence is wrong-

Push in and rotate phase inverter on 3-phase plug.

Machine vibrates excessively

*

Stand on uneven floor-

adjust stand for even support.

*Cutter head damaged-

replace cutter head immediately.

Cutting surface is bad

*dull cutter-

replace cutter

*Cutter knives blocked by chips-

remove chips.

*Cutting speed too low-

chose correct speed.

Содержание JWS-34KX

Страница 44: ...A 1 A 2 A 3 A 4 A 5 ...