ProPuls 320C

Operating manual

Page 51

Advantages

- high welding speed

- suitable for steel and non-ferrous metals

- virtually no welding spatter

- lower level of heat input due to a higher welding speed

- safer and deeper penetration with a higher rate of deposition

- higher welding speed in relation to normal spray arc

- saving of wage, material, gas and energy costs

- optimal side wall fusion and therefore, less undercut

- easy manipulation

Applications

- medium to heavy workpiece thicknesses

- steel, stainless steel and Aluminium processing operation

- automated and manual usability

Power range: 70A – 330/400/500A

Curves: Steel 1.2mm , stainless steel (Cr-Ni) 1.2mm

These welding processes are all synergic welding programs.

In order to facilitate operation, it is normally necessary to configure the right welding program and welding power.

All other parameters are regulated by the machine itself.

This allows operating personnel with little experience to achieve good welding results.

A variety of welding programs have already been saved in the machine.

(see program selection panel in the wire feed flap)

For the welding processes COLD / PIPE / POWER / FASTARC, all modes are available (pos. 3).

Thereby, the possible parameters can be set with functions Fx (pos. 4).

A detailed explanation can be found under the point 4 operating controls.

Using the MODE button, the desired welding process can be selected, e.g. MIG COLD.

By pressing the MATERIAL button again, the material menu opens.

With the left dial (pos. 2), the desired material can be selected in a display.

By pressing the ENTER / OK button, the parameters are accepted.

Subsequently, set the required welding power via 1 of the 3 possibilities available:

- Welding voltage V

(pos. 7) – not for COLD and PIPE

- Welding current A

(pos. 1)

- Material diameter mm (pos. 1)

These values are configured with the left dial (pos. 2). The respective value is shown in the right or left display.

The machine is now ready for welding.

For optimising the welding arc, the arc length (pos. 7) and the welding choke (pos. 7) can be configured

individually.

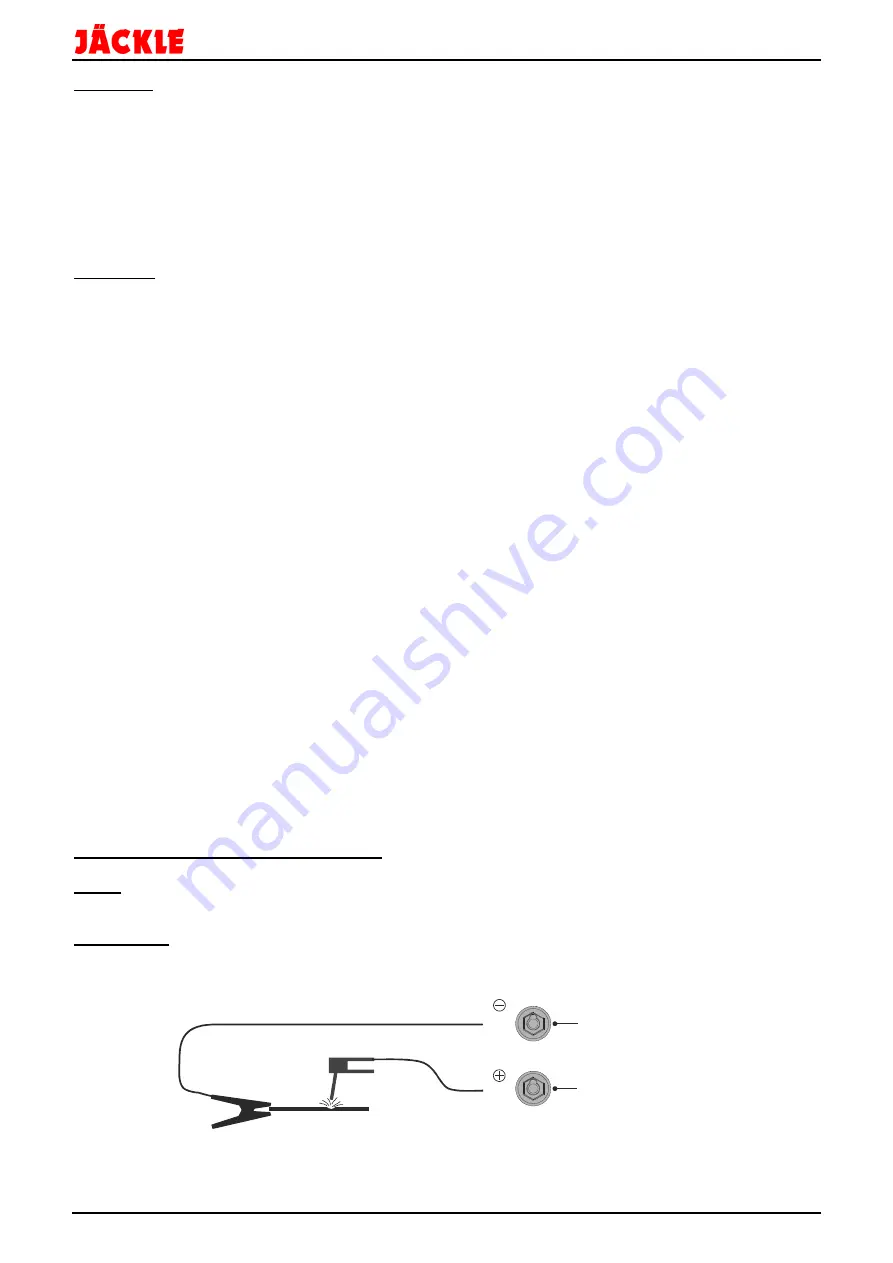

18.4 Electrode (MMA) welding / VRD

NOTE:

All functions and parameters are exactly described under point 16 control elements.

The functional sequence is described.

ATTENTION:

In the welding process ELECTRODE, the no-load voltage is applied to both output sockets.

Careful, risk of short circuits and electric shock!

Massebuchse

Workpiece socket

+ Buchse Elektrode / WIG

+ socket MMA / TIG

Vorne / front

Set the machine to the welding process ELECTRODE.

Содержание ProPuls 320 Compact

Страница 2: ......

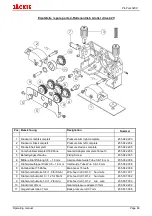

Страница 66: ...ProPuls 320C Operating manual Page 62 25 Ersatzteile spare parts Frontansicht front view...

Страница 68: ...ProPuls 320C Operating manual Page 64 Seitenansichten side view...

Страница 73: ...ProPuls 320C Operating manual Page 69 27 Schwei programme Program table...

Страница 74: ...ProPuls 320C Operating manual Page 70...

Страница 75: ......