‑

108

‑

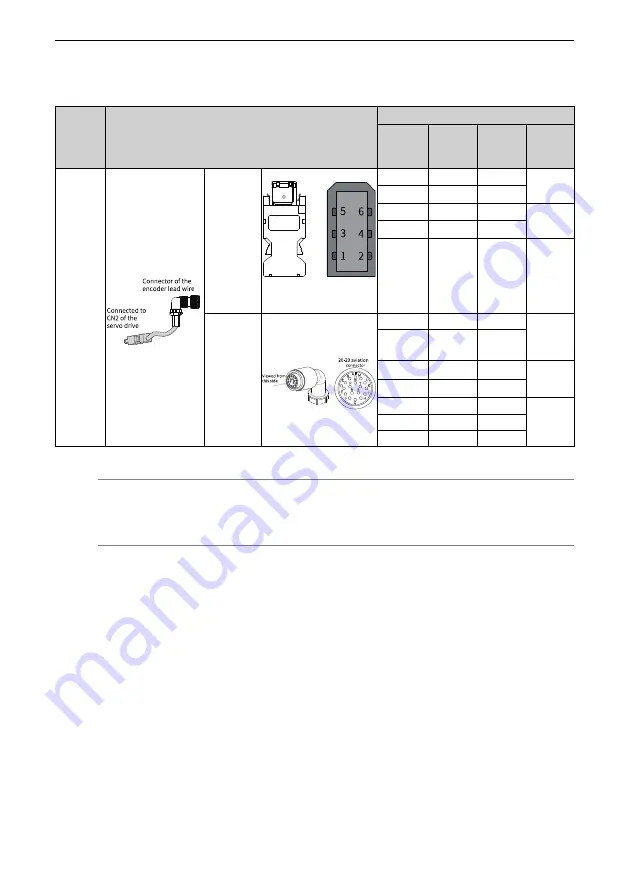

Table 3–29 Absolute encoder cable connector (MIL‑DTL‑5015 series 3108E20‑29S aviation

connector)

Applicable

Motor

Flange Size

[1]

Outline Drawing of the Connector

Terminal Pin Layout

Pin No.

Signal

Name

Color

Type

100

130

180

Servo drive

side

6‑pin male (The joint face

is on the right side.)

1

+5V

Red

Twisted

pair

2

GND

Orange

5

PS+

Blue

Twisted

pair

6

PS‑

Purple

Enclosure

PE

‑

‑

Motor Side

A

PS+

Yellow

Twisted

pair

B

PS‑

Yellow‑

black

E

Battery (+)

Blue

‑

F

Battery (‑) Blue‑black

G

+5V

Red

‑

H

GND

Black

J

Shield

‑

Note

[1] The flange size refers to the width of the mounting flange.

3.8

Connecting the Control Signal (CN1)

Observe the requirements in standard EN 60204‑1 during connecting control circuit

cables.

3.8.1 Wiring of I/O Signal Cables

I/O signal cable selection

It is recommended to use shielded signal cables to prevent I/O signal circuit from

being disturbed by external noise. Use separate shielded cables for different analog

signals. It is recommended to use shielded twisted pairs for digital signals.

Содержание SV660P Series

Страница 1: ...SV660P Series Servo Drive Hardware Guide Data code 19011391 A00...

Страница 55: ...Installation 54 Figure 2 21 Installing the ferrite clamp...

Страница 66: ...Wiring 65 3 3 2 Wiring Diagram for Torque Control Mode Figure 3 5 Wiring in the torque control mode...

Страница 111: ...Wiring 110 Open collector mode For use of the internal 24 V power supply of the servo drive...

Страница 113: ...Wiring 112 Scheme 2 Using the external resistor...

Страница 135: ...Wiring 134 Selecting the regenerative resistor Figure 3 48 Flowchart for selecting the regenerative resistor...

Страница 144: ...Maintenance 143...