2

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

Always wear eye protection

when operating or perform-

ing maintenance on this tool.

WARNING

WARNING

Always wear hearing

protection when operating

this tool.

Always turn off the air sup-

ply and disconnect the air

supply hose before instal-

ling, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before re-

suming use.

WARNING

Do not carry the tool by the

hose.

WARNING

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pres-

sure.

90 psig

(6.2bar/620 kPa)

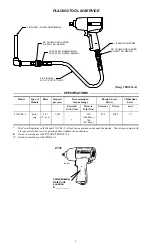

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 50

Ingersoll–Rand No. 115–1LB for routine external

lubrication of the impact mechanism through the Hammer

Case Grease Fitting.

Use Ingersoll–Rand No. 105–1LB or Ingersoll–Rand

105–8LB when disassembling and assembling the impact

mechanism.

Always use of an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – No. C18–03–FKG0–28

For International – C18–C3–FKG0

Do not mark any nonmetallic surface on this tool with

customer identification codes. Such actions could affect

tool performance.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)