27

USING THE POWER MANAGEMENT SYSTEM

Impact wrenches are not torque wrenches.

Connections requiring specific torque must be checked

with a torque meter after fitting with an air wrench.

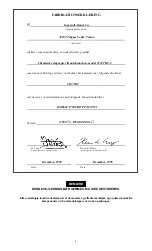

POWER

MANAGEMENT

DIAL

(Dwg. TPD1752)

Model 2131FRC–2 Impact Wrench incorporates a Power

Management System that is locked into power output

setting “C”. The Impact Wrench will always operate at

maximum power output in the reverse direction.

This power setting indicator on the rear of this tool is

locked in position “C”. Do not try to force

the

Regulator to another position. The power setting

indicator indicates a power output level, is for

reference only and DOES NOT denote a specific power

output.

The power output can be further reduced in forward

or reverse by using the variable throttle. Also, air

supply systems which do not deliver adequate air

pressure can affect power output at all settings.

MAINTENANCE SECTION

Always wear eye protection when operating or

performing maintenance on this tool.

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any

maintenance on this tool.

Do not test subassemblies unless they are installed in

the tool with the Hammer Case (15) installed and

properly secured to the Motor Housing (19). Failure to

do so could result in injury.

LUBRICATION

Each time a Model 2131FRC–2 Impact Wrench is

disassembled for maintenance and repair or replacement

of parts, lubricate the tool as follows:

1.

If the impact mechanism is not disassembled but

grease needs to be added, inject Ingersoll–Rand

No. 115–1LB Grease through the Hammer Case

Grease Fitting (17). If the impact mechanism is

disassembled, work approximately 14 cc (4.5 tsp) of

Ingersoll–Rand No. 105–1LB or No. Ingersoll–Rand

105–8LB Grease into the impact mechanism. Coat the

Anvil (8) lightly with grease around the Hammer

Case Bushing (16).

Be sure to grease the lug end of the Anvil.

2.

Use Ingersoll–Rand No. 50 Oil for lubricating the

motor. Inject approximately 1 to 2 cc of oil into the

air inlet before attaching the air hose.

DISASSEMBLY

General Instructions

1.

Do not disassemble the tool any further than

necessary to replace or repair damaged parts.

2.

Whenever grasping a tool or part in a vise, always use

leather–covered vise jaws to protect the surface of the

part and help prevent distortion. This is particularly

true of threaded members and housings.

Always use leather–covered vise jaws when

clamping the handle in a vise. Leather will

conform to the shape of the handle and allow the

tool to be held securely. To prevent damage to the

exhaust diffuser, never clamp only the bottom of

the handle.

3. Do not remove any part which is a press fit in or on

a subassembly unless the removal of that part is

necessary for repairs or replacement.

4.

Do not disassemble the tool unless you have a

complete set of new gaskets and O–rings for

replacement.

Disassembly of the Air Wrench

1.

Clamp the handle of the tool in a vise with

leather–covered jaws with the square driver

positioned horizontally.

Avoid excessive clamping pressure which can

damage the Housing and can cause difficulty when

removing the parts.

2.

Unscrew and remove the four Hammer Case Screws

(11).

3.

While lightly tapping on the end of the Anvil (8) with

a plastic hammer, lift off the Hammer Case (15) and

Hammer Case Gasket (18).

The Front End Plate (2) might come off during the

removal of the Hammer Case. Make sure that it

does not drop on the floor or strike a hard or

metallic surface since it might be damaged.

4.

Grasp the Hammer Frame (12) and carefully lift off

the entire impact mechanism, making certain not to

drop the two Hammer Pins (13).

Disassembly of the Impact Mechanism

1.

Set the mechanism, driver end up, on the workbench.

Note the twin hammers within the Hammer

Frame. These are identical, but must be placed in

the Hammer Frame in a certain relationship. Using

a felt–tipped pen, mark

he top T

↑

" hammer and

the bottom hammer B

↑

" with the arrows

pointing upward. Mark both Hammers on the

same end.

2.

With the mechanism sitting upright on the workbench,

slowly rotate the Anvil in a clockwise direction until

it comes up solid.