Triton Go Product Manual |

Wiring and Connections

INGENIA | 05/29/2017

78

DC tachometer

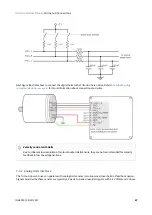

The Triton Go Servo Drive can use a DC tachometer for velocity feedback through the I/O connector. a DC

tachometer provides an analog signal whose voltage level is proportional to the rotor speed.

Next figure illustrates how to connect a DC tachometer with differential output to the Triton Go Servo Drive.

7.4.8 Feedback wiring recommendations

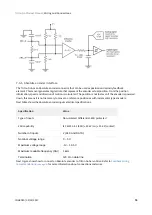

Signal distortion and electrical noise is a common problem in feedback signals

. These problems can result

in a bad position or velocity calculation for both digital feedbacks (gain or loss of counts) and analog feedbacks

(wrong voltage levels).To minimize these problems some

wiring recommendations

are shown:

•

Use differential signals

whenever is possible. That is, connect both positive and negative signals of

differential feedback sensors.

Use a twisted pair for each differential group of signals

and another

twisted pair for the +5 V supply and GND. Twisted-pairs help in elimination of noise because

disturbances induced in twisted pairs

•

Twisted-pairs help in elimination of noise due to electromagnetic fields by twisting the two signal leads

at regular intervals. Any induced disturbance in the wire will have the same magnitude and result in

error cancellation.

•

Connect the Triton Go and encoder GND signals

even if the encoder supply is not provided by the

drive.

•

Connection between Triton Go PE and the motor metallic housing is essential

to provide a low

impedance path and minimize noise coupling to the feedback. For further information, see

•

For better noise immunity, use shielded cables,

with the shield connected to PE only in the drive side.

Never use the shield as a conductor carrying a signal, for example as a ground line.

• It is essential to

keep feedback wiring as far as possible from motor,

AC power and all other power

wiring.

Recommendations for applications witch close feedback and motor lines

In some applications, like in the subsea market, where additional connectors and cables are a problem, the

feedback cannot be wired separately from the motor and power lines. This creates noise problems that could