Triton Go Product Manual |

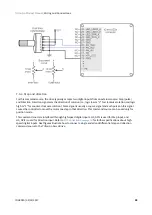

Wiring and Connections

INGENIA | 05/29/2017

97

77

http://doc.ingeniamc.com/display/EMCL/Sources

78

http://doc.ingeniamc.com/display/EMCL/ReManual

79

http://ingeniamc.com/software#motionlab

•

Encoder follower / electronic gearing

Analog inputs, step and direction, PWM command and encoder follower / electronic gearing are interfaced

through general purpose inputs. Next table illustrates which variables can be controlled with each command

source:

Command source

Target variable

Network interface

Position, velocity, torque

Standalone

Position, velocity, torque

Analog input (+/- 10 V o 0 – 5 V)

Position, velocity, torque

Step and direction

Position

PWM command

Position, velocity, torque

Encoder following / electronic gearing

Position

Please, see

documentation for configuration details.

7.6.1 Network communication interface

Triton Go Servo Drive can utilize network communication as a form of input command. Supported network

interfaces for Triton Go Servo drive are CAN (CANopen protocol), USB, RS-485 and EtherCAT.

USB interface is not suitable for long distances or noisy environments. This protocol is only recommended for

configuration purposes.

For normal operation, it is suggested to use CAN, RS-485 or EtherCAT. These interfaces are more robust against

noise than USB, and allow higher distances between the Triton Go Servo Drive and the commander. These

command sources can be used for setting position, velocity or torque target.

For further information, see

7.6.2 Standalone

Triton Go Servo Drive is provided with an internal non-volatile memory where a standalone program can be

saved. With the use of Ingenia

suite, the user can configure and save instructions to this 1 Mb

(128K x 8bit) EEPROM, allowing Triton Go Servo Drive to work in standalone mode. In this mode, there is no

need of any external command source.

Programs or macros composed with Motion Lab suite allow to

configure position, velocity or torque

targets

and to

interface with general purpose inputs and outputs.