8

icos system condensing -

Installation and Servicing

GENERAL

3

SYSTEM REQUIREMENTS

Notes

a.

The method of filling, refilling, topping up or flushing

sealed primary hot water circuits from the mains via

a temporary hose connection is only allowed if

acceptable to the local water authority.

b.

Antifreeze fluid, corrosion and scale inhibitor fluids

suitable for use with boilers having aluminium heat

exchangers may be used in the central heating

system.

Advice should be sought from a local water

treatment company.

THERMOSTATIC RADIATOR VALVES (TRV)

Caradon Ideal Limited

recommend that heating systems

utilising full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature in a space served by radiators not

fitted with such a valve as stated in BS. 5449.

When thermostatic radiator valves are used, the space heating

temperature control over a living area having a heating

requirement of at least 0.9kW (3000Btu/h) of the boiler heat

output should be achieved using a room thermostat whilst

other rooms are individually controlled by thermostatic radiator

valves. A higher proportion of TRVs may be used, provided that

a bypass between the boiler flow and return is fitted, to ensure

adequate flow when all TRVs are closed - however this is NOT

recommended as a large proportion of TRVs can restrict water

circulation and inhibit the condensing mode of condensing

boilers, reducing fuel economy.

For further information refer to the 'Good Practice Guide 143', a

publication of the Energy Efficiency Office, available from the

Building Research Establishment, Garston, Watford WD2 7JR.

Tel: 01923 664258.

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply.

The point of connection to the mains should be readily

accessible and adjacent to the boiler.

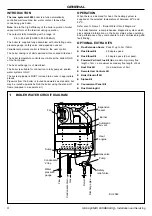

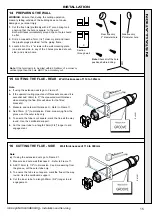

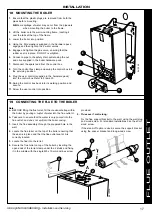

CONDENSATE DRAIN - Refer to Frames 28, 48

A condensate drain is provided on the boiler. This drain must

be connected to a drainage point on site. All pipework and

fittings in the condensate drainage system MUST be made of

plastic -

no other materials may be used.

IMPORTANT.

Any external runs must be insulated

The drain outlet on the boiler is standard 3/4in (21.5mm)

overflow pipe.

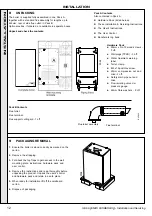

Safety valve setting

bar

3.0

Vessel charge pressure

bar

0.5 to 0.75

System pre-charge pressure

bar

None

1.0

System volume

Expansion vessel

(litres)

volume (litres)

25

1.6

1.8

50

3.1

3.7

75

4.7

5.5

100

6.3

7.4

125

7.8

9.2

150

9.4

11.0

175

10.9

12.9

190

11.9

14.0

200

12.5

14.7

250

15.6

18.4

300

18.8

22.1

For other system volumes

multiply by the factor across

0.063

0.074

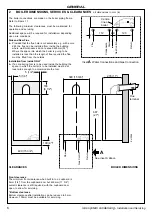

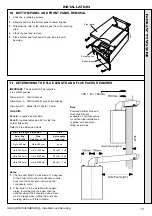

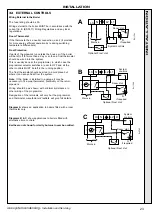

Pressure Drop Across Boiler

(metres w

ater)

0.5

1.0

Boiler Output (kW)

8.8

11.7

14.7

17.6

20.5

23.4

Ecl 1603

Graph 1 - Water flow rate and pressure loss

The hydraulic resistance of the boilers, at MAXIMUM OUTPUT, with

an 11

o

C (20

o

F) temperature differential, is shown in Graph 1.

Содержание icos system m3080

Страница 1: ......

Страница 51: ...51 icos system condensing Installation and Servicing NOTES ...

Страница 53: ......