29

icos system condensing -

Installation and Servicing

SERVICING

2077

Front panel

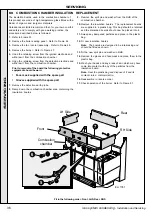

40 SERVICING SCHEDULE

To ensure the continued safe and efficient operation of the

appliance it is recommended that it is checked at regular

intervals and serviced as necessary. The frequency of

servicing will depend upon the installation condition and

usage but should be carried out at least annually.

It is the law that any service work must be carried out by a

registered CORGI installer.

Note.

Some aluminium oxide build-up on the heat engine

fins is usual with this type of condensing boiler.

Though removal is recommended annually, the heat

engine MUST be inspected and cleaned after a

MAXIMUM of 2 years operation

.

1.

Remove the boiler bottom panel - refer to Frame 43.

2.

Light the boiler and carry out a pre-service check, noting

any operational faults.

3.

Relight the boiler and operate for at least 10 minutes.

Check the gas consumption.

4.

Connect a suitable gas analyser to the sampling point on

the top of the boiler (refer to Frame 41) or into the flue

terminal if access is possible (optional test).

For correct boiler operation, the CO/CO

2

content of the flue

gas should not be greater than 0.004 ratio.

If this is the case, and the gas input is at least 90% of the

nominal, then no further action need be taken. If not,

proceed to Step 5 but see note above.

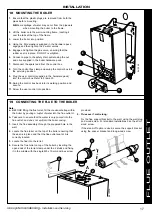

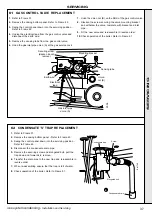

5.

Clean the main burner.

6.

Clean the heat engine.

Note.

This must be done with the heat engine and deposits

in a dry condition - refer to Frame 49.

7.

Check the main injector for blockage or damage.

8.

Wherever possible remove and clean the condensate trap

(refer to Frame 48) and check the drain for blockage.

9.

Check that the flue terminal is unobstructed and that the

flue system is sealed correctly.

The servicing procedures are covered more fully in Frames

41 to 50 and MUST be carried out in sequence.

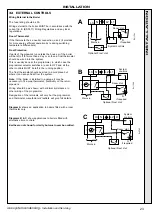

Note.

In order to carry out either servicing or replacement of

components the boiler front panel and sealing panel

must be removed - refer to Frames 42 and 44.

WARNING.

Always turn OFF the gas supply at the gas

service cock, and switch OFF and disconnect the electricity

supply to the appliance before servicing.

IMPORTANT.

10.

After completing the servicing or exchange of components

always test for gas soundness and carry out functional

checks as in 3 and 4 above.

11.

When work is complete the sealing panel MUST be

correctly refitted, ensuring that a good seal is made.

Do NOT OPERATE the boiler if the sealing

panel is not fitted

12.

If, for any reason, the condensate trap has been removed.

Ensure that the trap is re-filled with water before

re-assembly.

13.

Complete the service section in the Benchmark log book.

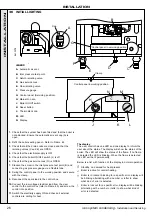

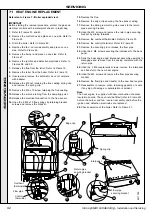

41 SAMPLING POINT

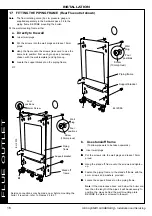

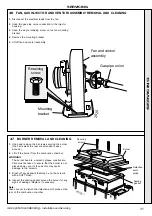

42 BOILER FRONT PANEL REMOVAL

1.

Remove the 2 securing screws.

2.

Pull the panel forward at the bottom and lift to disengage

it from the top lugs.

2056

Sample point

SER

VICING

Содержание icos system m3080

Страница 1: ......

Страница 51: ...51 icos system condensing Installation and Servicing NOTES ...

Страница 53: ......