332

Chapter

5

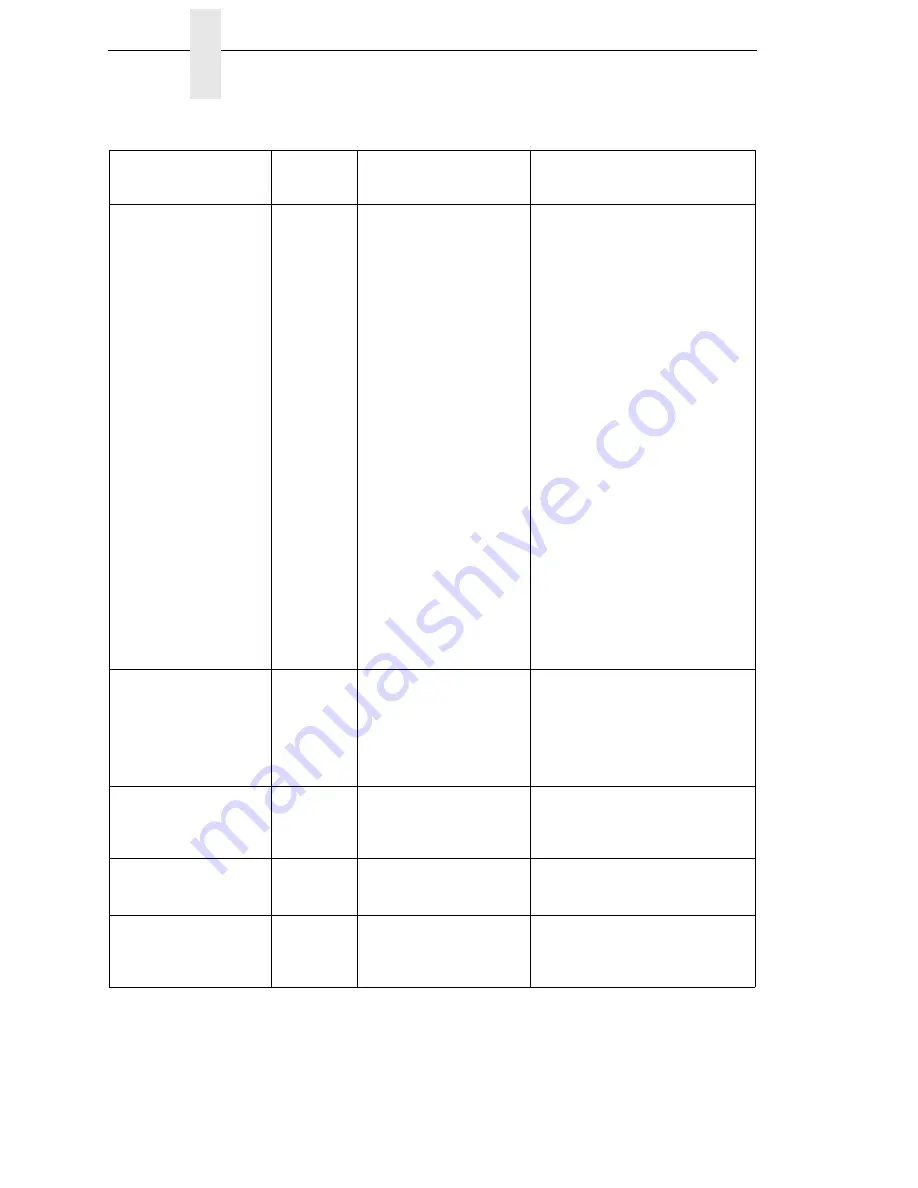

Restore The Printer To Operation

PAPER OUT

Load Paper

Yes

The printer does not sense

media:

•

Media was not installed

or has run out.

•

A break in media has

occurred.

•

Media was not routed or

installed correctly.

•

The media sensor is not

positioned correctly.

•

Media is installed

correctly, but the sensor

is not detecting it.

•

Gap/Mark Threshold

value may be set too

high and/or Paper Out

Threshold may be set

too low.

•

The printer detected a

false PAPER OUT

when changing from

Advanced Gap or

Advanced Notch to Gap

or Mark sensing or vice-

versa.

1. Install media. If a break occurred,

reinstall the media. Press the

PAUSE key to clear the fault

message. Check the media

installation procedures on page 44.

2. Verify the lower media sensor is

properly positioned under the

media. If Advanced Gap or

Advanced Notch is selected, verify

the upper media sensor is

positioned above the lower media

sensor. Run Auto Calibrate to

improve the ability of the sensor to

detect the installed media.

3. Check if the Gap/Mark Threshold is

too high or the Paper Out Threshold

is too low. Lower the Gap/Mark

Threshold or raise the Paper Out

Threshold value.

4. If using media with no gaps or black

marks, perform Auto Calibrate to

establish a valid Paper Out

Threshold.

5. If the printer detected a false

PAPER OUT when changing from

Advanced Gap or Advanced Notch

to Gap or Mark sensing or

vice-versa, press the PAUSE key

and run Auto Calibrate.

PAPER OUT

TIMEOUT

Yes

In the CT emulation with a

coax interface, a time-out

message is sent to the host if

paper is not loaded within 10

minutes after PAUSE was

pressed to clear a paper out

fault.

Load media and run a print test. If the

message persists, contact your

authorized service representative.

PARITY ERROR

Yes

Parity error (serial interface).

Check your serial host interface

parameter settings. If necessary,

change them so they match the

settings of the attached host.

POOR SCANNING

Check Head&Heat

Yes

Data validation failure:

The ratio between bar code

elements is too small.

Adjust heat/speed/pressure.

POOR SCANNING

Check media

Yes

Data validation failure:

The bar code is only good in

small bands that are difficult

to scan.

Check for ribbon wrinkle. Roll wrinkled

area onto take-up spindle.

Table 17. LCD Message Troubleshooting (continued)

Displayed Message

Can User

Correct?

Explanation

Solution

Содержание InfoPrint 6700 Series

Страница 1: ...User s Manual Infoprint 6700 Series Thermal Printer Form Number G550 0449 00 ...

Страница 2: ......

Страница 3: ...Infoprint 6700 Series Thermal Printer User s Manual ...

Страница 17: ...www ibm com printers register ...

Страница 18: ......

Страница 24: ...Table of Contents ...

Страница 38: ...38 Chapter 1 Setting Up The Printer ...

Страница 86: ...86 Chapter 2 Cleaning ...

Страница 95: ...Loading A Saved Configuration 95 Figure 3 Sample Configuration Printout ...

Страница 96: ...96 Chapter 3 Overview Sample Configuration Printout cont ...

Страница 97: ...Loading A Saved Configuration 97 Sample Configuration Printout cont ...

Страница 98: ...98 Chapter 3 Overview Sample Configuration Printout cont ...

Страница 99: ...Loading A Saved Configuration 99 Sample Configuration Printout cont ...

Страница 100: ...100 Chapter 3 Overview Sample Configuration Printout cont ...

Страница 178: ...178 Chapter 3 IPDS IPDS Setup Print IPDS Fonts cont Figure 5 IPDS Fonts 3816 Emulation Sample Printout 5504 ...

Страница 296: ...296 Chapter 3 DATE ...

Страница 306: ...306 Chapter 4 RS 232 And Optional RS 422 Serial Interfaces ...

Страница 344: ...344 Appendix A ...

Страница 350: ...350 Appendix B Ordering Supplies And Accessories ...

Страница 360: ...360 Appendix E Installing The Media Cutter Tray ...

Страница 366: ...366 Appendix F ...

Страница 383: ......

Страница 384: ...Printed in U S A G550 0449 00 07G550044900 179403 001A 179403 001 ...