Installation and Maintenance Manual

37

Detector Installation Guide, continued

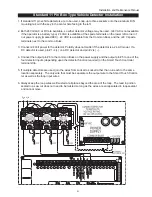

Like This NOT Like This OR This

Loop Sealant

9. Follow this guide for the correct number of wire turns according to the perimeter size of the loop:

10 to 13 lf. = 5 turns 14 to 26 lf. = 4 turns 27 to 45 lf. = 3 turns 46 to 100 lf. = 2 turns

10. This guide is written from a design perspective, but installation workmanship practices are equally

important to insure proper operation and long loop life. The best way to insure a quality installation is to

employ a professional installer experienced with detector loops. A few important practices are:

•

The slot in the surface should be cut ¼” wide x 1 ½” deep.

•

The corners of the cut must be at an angle or core drilled to relieve stress on the wires.

•

After the wire is installed, the slot must be completely backfilled with a non-hardening sealer.

Note that if the loop wires are able to move in the slot after the sealer has set, the detector may

give false calls

Detector Logic

Hy-Security Gate Operators recommends that vehicle detectors be used for free open and obstruc-

tion sensing logic only. The exception is in parking applications with our HTG 320 operator where

detectors may be also used to close the gate. In applications employing our swing, vertical lift, or

sliding gate operators, closing logic cannot be used. Because of their slower speeds, closing logic

is a poor choice for security gate systems. Since there are several ways that the gate may be left

standing open and because there is a loss of safety.

Loop Diagnostics

The following tests cannot guarantee a functioning loop, but failure of either test means that the

loop is definitely suspect, even though it may still be functioning at the time.

Test #1:

Resistance of the loop and lead-in wire should not exceed 4.0 Ohms.

Test #2:

The resistance to earth, as measured with a 500V “Megger”, should be 100 Megohms or more.

Loops may function at 10 Megohms or less but will not be reliable (e.g. when the ground is wet from

rainfall). Low resistance indicates broken or moisture saturated insulation. This is common if inap-

propriate wire insulation has been used.

Also see section titled “Detector & Loop Fault Diagnostics” on page 42 for additional tests that may

be performed with Hy-Security HY-5A mini detector modules.