Installation and Maintenance Manual

32

Placement and Use of Secondary Pedestrian Entrapment Sensors

WARNING: To reduce the risk of serious injury or death, read and follow all instructions in

the gate operator handbook and on the warning labels.

Automatic gate operators are intended only for vehicular use and pedestrians must be routed to a

separate man gate, however sensors are still required in order to provide a degree of protection

should anyone happen to stray into the area of an automatic gate. Generally there are two types of

external sensors that may be used: Contact type sensors, such as an edge sensor, and non-

contact sensors, such as photoelectric eyes. Current industry standards require the use of either

type or both of these sensors, as a secondary device, in Class I and Class II automatic sliding gate

installations, because the general public is likely to be present. Although there are alternatives for

Class III and IV installations, we highly recommend the use of external sensors for all automatic

gate applications.

The specifier or installer may choose either photoelectric eyes or edge sensors, or use these

devices in combination, but both the open and closing directions of gate travel must be guarded.

The UL 325 standard for automatic sliding gates specifically requires the following:

•

One or more non-contact sensors (photoelectric eyes) shall be located where the risk of entrap-

ment or obstruction exists, such as the perimeter reachable by a moving gate.

•

One or more contact sensors (edge sensors) shall be located at the leading edge, trailing edge

and post mounted both inside and outside of a sliding gate.

•

A hardwired contact sensor shall be located and it’s wiring arranged so that the communication

between the sensor and the gate is not subjected to mechanical damage.

•

A contact sensor that transmits its signal to the gate operator shall be located such that the

signal is not impeded by building structures or other obstructions and shall function under its

intended end-use conditions.

•

The contact and non-contact sensors must be tested and labeled as “Recognized Components”

under the UL 325 standard in order to be deemed acceptable for use in this application.

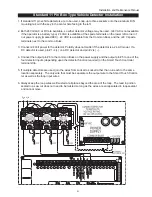

Study the entrapment protection schematic and consider your specific installation to deter-

mine where the greatest risks of entrapment exist. Locate edge sensors and/or the photo-

electric sensors accordingly. Be certain that a sufficient number of sensors are used so that

both directions of gate travel are properly guarded.