Installation and Maintenance Manual

35

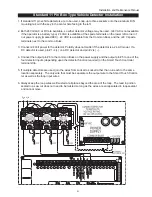

Installing Photoelectric Sensors, cont.

Supervised Connection:

If the photo eye being installed has a true NC output (one that is NC when the photo eye is pow-

ered, aligned and set for Light Operate) then a supervised connection is recommended. A super-

vised connection will signal a system Fault and prevent gate operation if either the open or close

photo eye connection ever becomes an open circuit or a short circuit. The Installer Menu item

[PC_0] must be changed to [PC_1] to enable this feature. See Installer menu 18 on page 26.

Photo Eye Function:

A tripped photo eye will prevent the gate from starting in either direction if the gate is stationary. If

tripped while in motion, the standard function is to pause the gate motion and then automatically

restart again if the photo eye is clear within five seconds.

An optional setting in the Installer Menu

will cause a 2 second reversal of travel. See Installer menu 14 & 15.

Alignment:

Most photo eyes require careful optical alignment in order to aim the emitter beam to the center of

the receiver or reflector. In order to avoid false triggering, it is important to carefully align the

system, especially with retro-reflective photo eyes. The best way to assure true centering of the

beam is with some trial testing where the emitter is shifted to move the beam left and right and up

and down until the range of the invisible cone of the infrared beam is known. Photo eyes usually

provide alignment aid LED’s for this setup, but they can be hard to see. Hy-Security has provided a

unique feature that causes our buzzer to chirp when the photo eye enters and exits alignment. See

User menu 9. Set the Installer menu item [PE_0] to [PE_1] and the buzzer will provide an audible

indication both when the beam is broken and remade.

Notes about retro-reflective systems:

Correct installation and alignment of a retro-reflective photo eye and its reflector is important for a

trouble free installation. Any system operating at a range greater than 16 feet is more prone to

false triggering due to dirty optics, condensation or poor weather. If care is taken in the initial

mounting and alignment of the 3-inch reflector, the chance of problems is greatly reduced.

Taking steps to protect the photo eye and the reflector from being exposed to fog and being abso-

lutely certain the photo eye is perfectly aligned will greatly reduce any false triggering of the system.

The ideal mounting of a retro-reflective photo eye is inside and enclosure of some sort.

The ideal mounting for the reflector is suspended inside a twelve inch long piece of 3-inch PVC

conduit. Cut the opening of the PVC conduit at a 45-degree angle to act as a drip shield. Hold the

reflector against the backside of the PVC conduit by attaching a 3-inch male connector. Do not

cement the connector, so that the reflector can be reached for future cleaning. To create a mounting

base, attach a 3-inch aluminum flange (electric meter hub) to the connector. This whole package

can be mounted to any flat surface.

Locate the reflector in the center of the invisible beam of infrared light to achieve the most sensitive

alignment. The beam center is determined by the following test: while holding the reflector in your

hand, slowly raise it until the beam is no longer returned, and the photo eye trips. Mark this maxi-

mum height. Now lower your hand and determine the lower limit of the infrared beam by watching

for the trip point. Mark this position as well. Repeat the same procedure for left and right at the

center elevation of the beam, as determined by the previous test. Once the four limits have been

determined, either mount the reflector in the center of the area outlined or realign the eye for the

position of the reflector. If the photo eye is realigned, be sure to perform the centering test again to

verify that the reflector is truly in the center.