Installation and Maintenance Manual

36

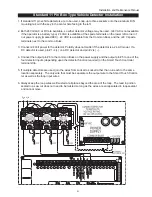

Twist lead-in at least 10 turns per foot

Like This

Not Like This

Twist Like This

Detector Installation Guide

Detector Basics

The vehicle detector passes a small current flow through the “loop” which then becomes an induc-

tive coil. When a vehicle passes over a loop the detector senses the resultant drop in the induc-

tance, and actuates the detector output.

Loop Configurations

Configurations differ depending on the application. In parking applications with our HTG 320 opera-

tor, a loop may be as small as 3’ x 6’. In a traffic application employing one of our sliding gate,

swing gate or vertical lift gate operators, the smallest loop should not be less than six feet square.

Rules to Follow for Security Gate Applications

1. The side of the loop closest to the gate shall be located at least four (4) feet distant from its line of

travel.

2. The shortest side of the loop shall be between six (6) and eight (8) feet in length. The longest side of

the loop shall be between six (6) and twenty (20) feet in length. For applications that need to span a

wide area, use several smaller loops. Do not exceed a maximum of 200 square feet of loop area to

only one detector.

3. In applications with multiple loops, keep each loop at least six feet apart. This avoids “cross talk”. It is

possible to have loops closer together by selecting different frequencies. An advantage of using Hy-

Security model HY-5A detectors is that problematic “cross talk” is not possible.

4. For greater sensitivity and less chance of false calls caused by the motion of the gate, it is better to

use two smaller loops, connected in a series circuit, to one detector instead of one large, single loop.

5. To avoid interference, keep loops at least two (2) inches above any reinforcing steel. Do not route loop

wires with, or in close proximity to, any other conductors, including other loop leads, unless shielded

lead-in cable is used.

6. Loop and lead-in wire should be one continuous piece. Avoid splices, if possible. If a splice is neces-

sary for any reason, “pot” the splice in epoxy or use heat shrink to ensure that the quality of the splice

covering is the same as the original wire jacket.

7. Use only 14, 16 or 18 gauge stranded wire with a direct burial jacket. Cross linked polyethylene insula-

tion types, such as, XLPE or XHHW, will last much longer and are less prone to damage during

installation than conventional insulation types. Preformed loops can be used before road surfacing or

under pavers.

8. Twist loose tails of lead-in wires tightly, approximately ten times per foot.