5

– 1

Chapter 5 Maintenance

In order to use the PLC in the best condition and maintain the system to operate properly, it is necessary to conduct

daily and periodic inspections.

5.1

Daily and Periodic Inspection

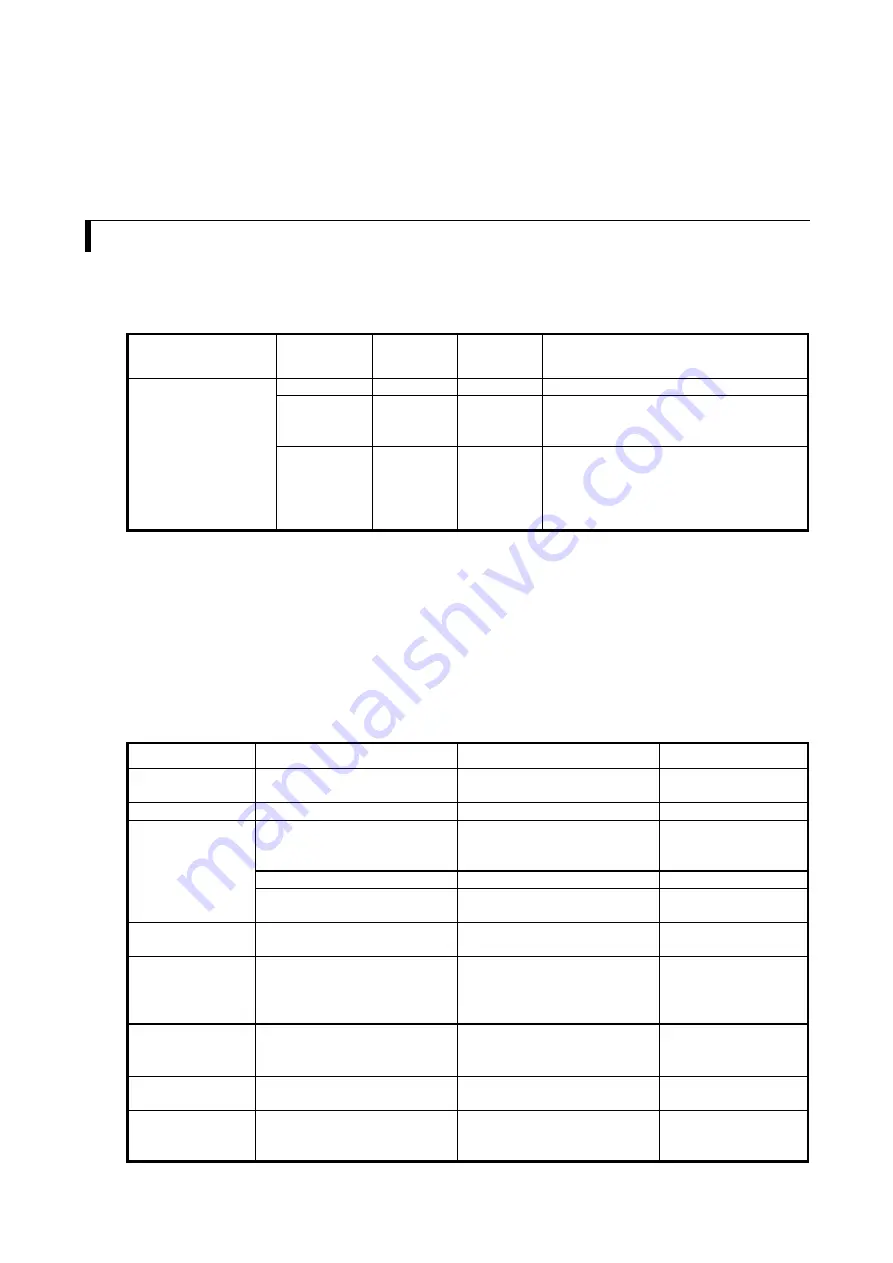

(1) Daily inspection

Verify the following items while the system is running.

Table 5.1 Items for daily inspection

Item

LED display

Inspection

method

Normal status

Main cause of error

Unit LED display

POW

Visual check

ON

Power supply error, etc.

RUN

Visual check

ON

(

Running

)

OFF:

Microprocessor error, memory error, etc.

Refer to chapter 3 for further information.

OK

*1

Visual check

ON

OFF:

Serious errors such as microprocessor error or

memory error, etc. Refer to chapter 3.

Blink:

Battery error (71 error)

*2

*1

MICRO-EHV+ indicates the error by the lighting pattern (ON / blink / OFF) of OK LED.

*2

If the power isn’t supplied without replacing the battery after battery error detected (OK LED blinking), retain data and

realtime clock data could be lost due to battery empty. If power off time is long enough, it is possible that a battery

becomes empty while this power failure. In that case, retain data and realtime clock data would be already lost in the

next power up.

(2) Periodic inspection

Turn off the power for the external I/O circuit, and check the following items once every six months.

Table 5.2 Items for periodic inspection

Part

Item

Check criteria

Remarks

Programming device

to CPU

Check the operation of the

programming device

All switch and display lamps work

properly.

Power supply

Check for the voltage fluctuations

85 to 264 V AC

Tester

I/O

Output relay life

Electrical life 200,000 times

Mechanical life 20 million times

Refer to the relay contact

life curve in the section

4.1 Installation.

LED

Turns ON/OFF correctly

External power voltage

Within the specification for each

I/O.

Refer to the Chapter 2

Specifications

Battery

(Lithium battery)

Check voltage and life

OK LED blinks.

Within 2 years after replacement.

Installation and

connecting areas

(1) All units are securely fixed.

(2) All connectors fit snugly.

(3) All screws are tight.

(4) All cables are normal.

No defects

Tighten

Check insertion

Tighten

Visual check

Ambient environment (1) Temperature

(2) Humidity

(3) Others

0 to 55

C

5 to 95 % RH (no condensation)

No dust, foreign matter, vibration

Visual check

Spare part

Check the number of parts, the

storage condition

No defects

Visual check

Program

Check program contents

Compare the contents of the latest

program saved and CPU contents,

and make sure they are the same.

Check both master and

backup.

Содержание EH-A14EDR

Страница 6: ...MEMO ...

Страница 10: ...MEMO ...

Страница 141: ...Chapter 3 Programming 3 81 Program ...

Страница 166: ...Chapter 5 Maintenance 5 4 MEMO ...

Страница 170: ...Appendix A1 4 MEMO ...