Worksheet 1:

Recommended Line Sizes

Copyright © 2011 Haskris Company

36

www.haskris.com

Version R1600-X-R407C-XXX Instruction Manual Rev00

This worksheet is designed to provide guidance in selecting an appropriate nominal

piping size between Haskris Model R1600 and Haskris Model WW4.

This worksheet assumes:

•

All municipal, local and state codes will be followed.

•

Type L copper piping will be furnished.

•

The loop of hose installed for WW4 is 1½” ID.

•

All piping internal to the R1600.

•

A 35% propylene glycol/water solution will be furnished.

DO NOT USE AUTOMOTIVE ANTIFREEZE.

DO NOT USE AUTOMOTIVE ANTIFREEZE.

DO NOT USE AUTOMOTIVE ANTIFREEZE.

DO NOT USE AUTOMOTIVE ANTIFREEZE.

•

The R1600 pumping system will not to be used to fill glycol loop.

Begin calculations with 1-½”nominal piping. Increase to next larger nominal pipe size if

baseline number (335) is exceeded, or re-configure piping run using 90º LR Elbows

(Recommended).

Find total length of pipe run (Supply and Return):

Find total length of pipe run (Supply and Return):

Find total length of pipe run (Supply and Return):

Find total length of pipe run (Supply and Return):

Estimated pipe run (start with 1-½” nom. size) Total run (ft.) _______________ (A)

Find total number of fittings:

Find total number of fittings:

Find total number of fittings:

Find total number of fittings:

90º Elbows _____________ x factor from chart ______ = ______________ (B)

90º LR Elbows __________ x factor from chart ______ = ______________ (C)

45º Elbows _____________ x factor from chart ______ = ______________ (D)

Add (A) + (B) + (C) + (D)

Add (A) + (B) + (C) + (D)

Add (A) + (B) + (C) + (D)

Add (A) + (B) + (C) + (D)

______________ (E)

Divide (E) by 100

Divide (E) by 100

Divide (E) by 100

Divide (E) by 100

(E/100)

(E/100)

(E/100)

(E/100)=

=

=

= ________________(F)

Multiply (F) by Head loss (For 1

Multiply (F) by Head loss (For 1

Multiply (F) by Head loss (For 1

Multiply (F) by Head loss (For 1----½”

½”

½”

½”=5.61)

=5.61)

=5.61)

=5.61) (F X HL)=

(F X HL)=

(F X HL)=

(F X HL)= ______________ (G)

Multiply (G) by 1.26

Multiply (G) by 1.26

Multiply (G) by 1.26

Multiply (G) by 1.26 (glycol factor): <

: <

: <

: <

Maximum Value 17

Maximum Value 17

Maximum Value 17

Maximum Value 175>

5>

5>

5>

_________ (I)

If (I) is less than or equal to 175 then your pipe size is 1-1/2”. If not, repeat the

calculations using the next larger nominal pipe size. Continue in this manner until

(I) is less than or equal to 175 to find your recommended line size.

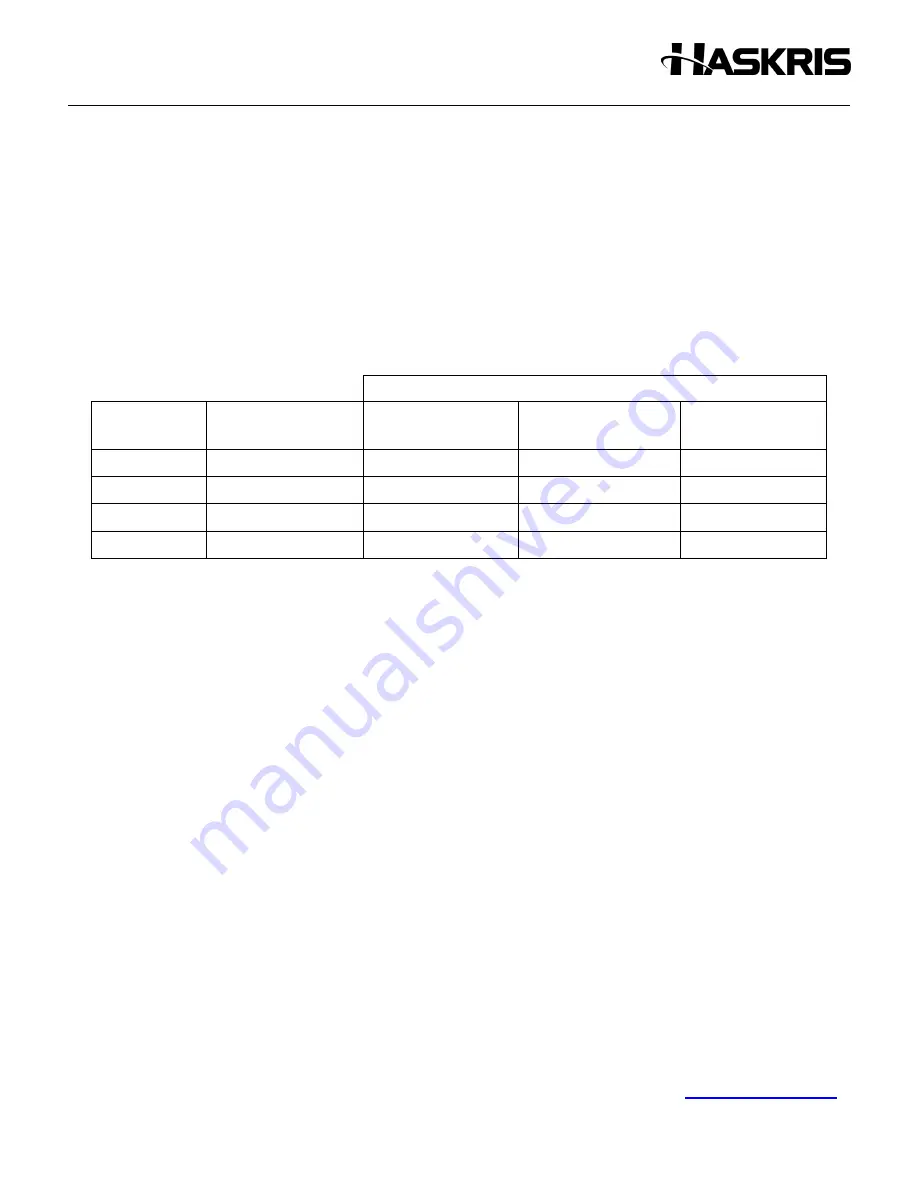

Equivalent length of pipe in feet

Nom. Pipe

Size

Head Loss per

100’ (HL)

90º Standard

(Close) Elbow

90º Long Radius

(LR) Elbow

45º Elbow

1-½”

5.61

4.1

2.7

1.9

2”

1.57

5.2

3.5

2.4

2-½”

0.55

6.2

4.2

2.9

3”

0.246

7.7

5.2

3.6