16 HASCO hot runner

5.3.1 Setup

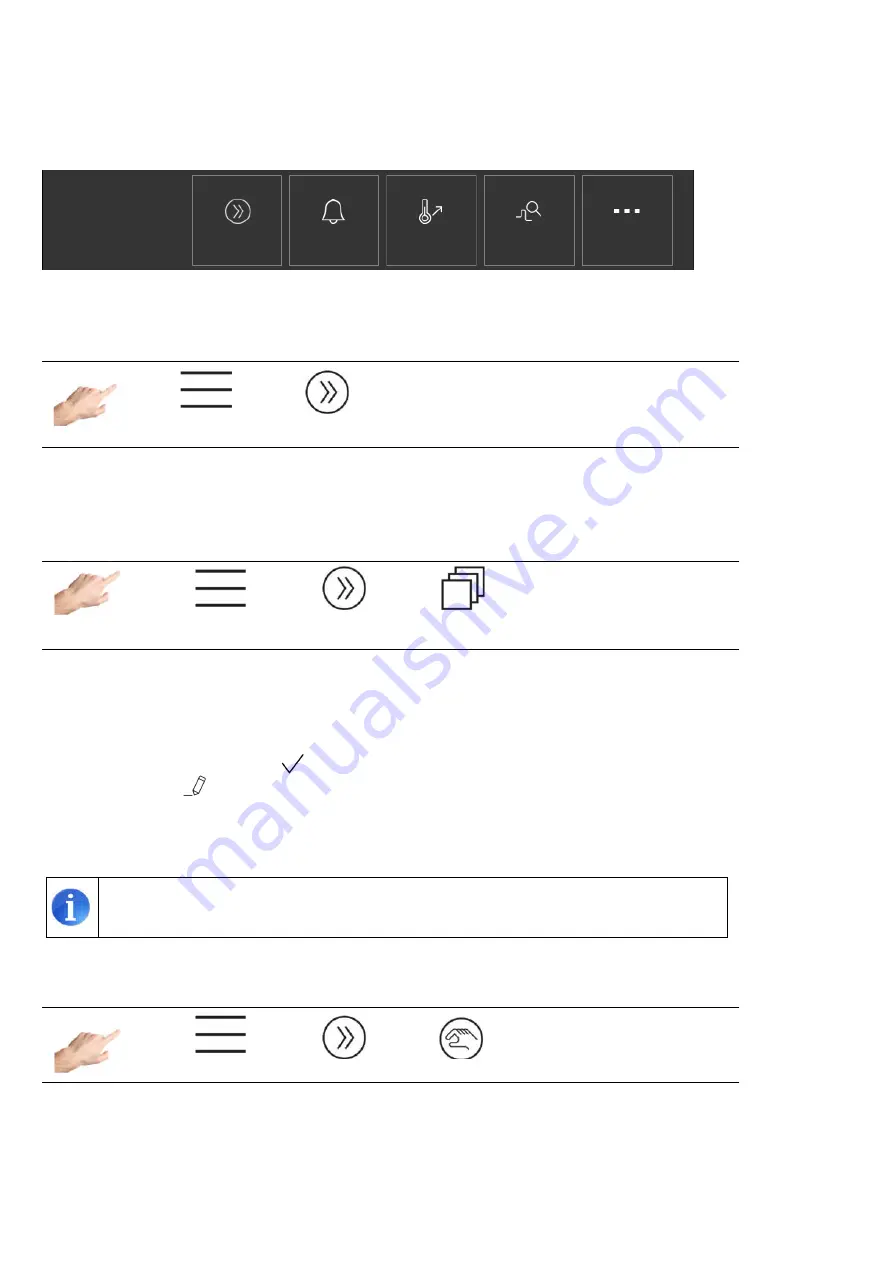

All the mould-specific settings must be made during setup. The quick start guides users through the key settings for

bringing the controller into operation as quickly as possible. The "Monitoring" menu item is used for monitoring process

values and setting the corresponding limits. "Heating" contains all the functions that can influence the heating process.

"Mould test" is used to test the correct wiring of sensors and heating units. This function is particularly useful after initial

installation or after mounting operations.

Figure 10 -

Setup

The individual functions are explained in more detail below.

5.3.1.1

Quick start

1.

2.

Setup > Quick start

The basic zone settings can be entered in quick start. Zones can be grouped here and setpoint temperatures and

operating modes entered for the zones.

5.3.1.1.1 Groups

1.

2.

3.

Setup > Quick start > Groups

Zones can be combined into groups, considerably facilitating operation. It makes sense, for example, to allocate the

zones for nozzles and manifolds to different groups. In this way, the grouped zones can be easily selected for

simultaneous operation later on. If no groups are to be defined, this section can be skipped.

Procedure: First select the zones on the left that are to be made into a group. Then, on the right side, click on one of the

predefined groups and adopt it with

. The names of the groups are pre-set by default to Group 1... Group 9 and can

be adapted with the

symbol where required. In addition, each group is represented by a colour. Zones that are

assigned to a group indicate this by the corresponding group colour beneath the zone name. See Figure 8 - Sample

page for entering setpoint values.

Factory setting:

All zones without a group

5.3.1.1.2 Operating mode

1.

2.

3.

Setup > Quick start > Operating mode

In the "Operating mode" menu item, a specific operating mode can be entered for each zone.

Procedure:

First select the zones on the left whose operating mode is to be changed.

Quick start

Monitoring

Heating

Mould test

Others

Setup

Mould-specific

Groups

Operating mode

Setpoint values

Temperature

Sensor fracture

Residual current

Output level

Heating group

Ramp gradient

Soft start

Run

Settings

Sensor type

Output level