MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

25

3.7.3.2

Relief Valve and Piping

Each boiler is supplied with a pressure-relief valve sized in accordance with ASME requirements. The relief valve

must be piped to a suitable drain prior to placing the boiler into service and in a manner that prevents water spray

from contacting any person. Reducing couplings or other restrictions are not permitted in the discharge line.

Do not plug or obstruct the discharge of the relief valve.

3.7.3.3 Low

Water

Cut-off

The boiler is furnished with a flow-switch-type low water cut-off as required by the ASME BPV Code, Section IV.

No field piping is required. If the flow switch does not sense water flow, the boiler will shut down and a red

indicator will be illuminated on the control panel.

Installation of an external low water cutoff or manual reset low-water switch may be required by certain codes or

in certain installations. Consult your local code for details.

Never install a valve that can isolate the low water cut-off from the boiler.

3.7.3.4

Drain Valve and Piping

The boiler is provided with external drain connections. A drain valve is installed in the bottom of the boiler. Prior

to draining the boiler for maintenance or testing, electrical power and gas supply must be turned off to the boiler.

The boiler must then be isolated from the system at the supply and return connections prior to draining water from

the boiler.

NOTICE!

This drain valve is installed for draining of the boiler water only, not the entire system. Draining of the

system through the boiler will result in depositing sediment from the system in the boiler which will result in poor

heat transfer characteristics of the boiler and early boiler failure.

3.7.4

Flushing and Filling

3.7.4.1

Flushing the System

Before filling the boiler, flush the system to remove the debris. Clean and flush old piping thoroughly before

installing the boiler as recommended by your water conditioning or chemical treatment supplier.

Under no circumstances should the hydronic system be flushed while the boiler is attached to the system since

the debris or corrosion products could accumulate in the boiler and plug the boiler heat exchanger.

If the piping system attached to this unit will be chemically cleaned, the boiler must be disconnected from the

system and a bypass installed so that the chemical cleaning solution does not circulate through the boiler.

3.7.4.2 Filling

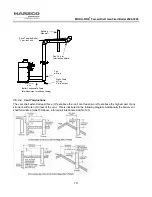

To insure that no air is trapped during the filling process, open the pressure-relief valve located at the rear of the

boiler prior to filling the boiler. While filling, leave the relief valve open until a steady flow of water is observed.

Close the valve and finish filling the system.

3.7.5 Water

Quality

The boiler is designed to operate in a closed-loop system using water or water/glycol only. As such, the system

should be tight and not require make-up water. A high percentage of untreated make-up water can cause

premature failure due to build up of scale. Such failure is not covered by warranty.

Scale can also reduce efficiency. For example, a scale thickness of 1/16 inch will result in a 12.5% loss of

efficiency.

Содержание 1004905923

Страница 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

Страница 31: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 31 Ratio V Adjust at Hi Fire Bias N Adjust at Low Fire ...

Страница 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

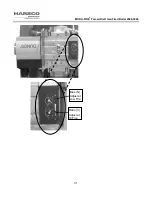

Страница 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Страница 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Страница 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...