MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

36

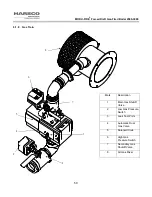

9. Check the gray grafoil gaskets around the burner flange for cracking. Replace if necessary. Replace the

red silicone gasket on the heat exchanger head.

10. Clean the burner to remove any soot or foreign material that may have accumulated. Blow the burner with

compressed air or wash off (do not scrub or use wire brush).

11. Use a soft, clean cloth to remove accumulated contaminants from the UV detector/scanner glass

envelope.

12. Before re-installing the burner, check the cleanliness of the heat exchanger and the condition of the

combustion chamber. If corrosion or leaks are noticed, please call for service.

13. Re-install components in the reverse order of removal. Be sure to reinstall all gaskets, O-rings and

electrical connections. Be sure the gas valve flange and O-ring is assembled correctly to prevent gas

leaks.

14. Reinstall all covers.

15. Fire Test the boiler and use a combustion analyzer to ensure that the fuel/air ratio is set correctly. If

adjustment is required, refer to section 3.14.1.

5.3 R

EMOVING THE

H

EAT

E

XCHANGER

Heat Exchanger is heavy and may cause injury if improperly handled. Removal of the

heat exchanger should be performed only by knowledgeable and experienced personnel.

5.4 A

FTER

A

LL

R

EPAIRS OR

M

AINTENANCE

1. Follow "Pre-Start Check List" (Section 3.10) and all "Safety Checks" (Section 3.11) and verify proper

operation.

2. Fire the Boiler and perform combustion check.

3. Adjust gas flow if necessary. (See "Gas Pressure Adjustment", Section 3.14.1)

5.5 S

EQUENCE OF

O

PERATION

1. In order for the boiler to start, the following limits must be satisfied:

a) Water flow switch

b) High & low gas pressure switches

c) High temperature limit

d) High back pressure switch

e) High stack temperature switch

2. When the Boiler On/Off switch is turned on, power is provided through a circuit breaker to the boiler control

and the combustion blower.

3. If the high gas, low gas or low water level control is open, the boiler control locks out and displays an error.

4. When the water temperature is below the boiler control setpoint minus the hysteresis (On Differential), a heat

request is generated.

5. Provided all limits are made, the boiler will attempt to start.

Содержание 1004905923

Страница 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

Страница 31: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 31 Ratio V Adjust at Hi Fire Bias N Adjust at Low Fire ...

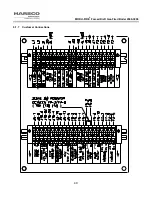

Страница 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

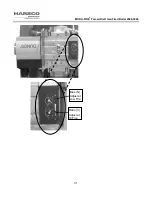

Страница 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Страница 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Страница 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...