85

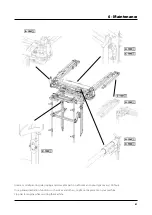

6 - Maintenance

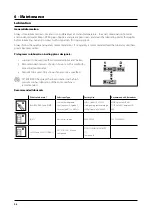

Service and maintenance intervals

General information

The maintenance and replacement intervals of the elements listed as follows will depend on the conditions under which

the mistblower will be used, and hence impossible to assess.

WARNING! If you do not feel confident in carrying out some of the maintenace jobs described below, then

contact your HARDI dealer’s workshop for assistance.

Every 10 working hours – Spray circuit

Fill the tank with clean water, activate all the functions and check for leaks using higher spray pressure than normal.

Check visually the cone of the nozzles to detect for imperfections.

Every 50 working hours – Transmission shaft, chassis, air pressure and diaphragm pump

Check the condition of the transmission shaft protection guard. Replace any damaged parts as required.

Re-tighten the bolts of the wheels and the areas under the greatest stress or torque.

Check/adjust tyre pressure.

Check/adjust pressure in pump pressure pulsation damper.

Grease the diaphragm pump.

Every 100 working hours – Drawbar

Grease the drawbar or ball of the mistblower.

Check that the pivoting axles are not blocked or deformed.

Grease and oil all moveable parts.

Every 250 working hours – Wheels, brakes, hoses and gearbox

Check and grease the hub and the wheel braking system.

Verify the hydraulic brake.

Check all the hoses in the circuit.

Check the gearbox support and re-tighten the bolts holding it in place.

Every 1000 working hours – Full service

Perform a full service on all the parts described previously.

Change the gearbox oil.

Dismantle and grease the transmission shaft and joints going through the main tank.

Dismantle the fan clutch and clean/lubricate.

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...