98

6 - Maintenance

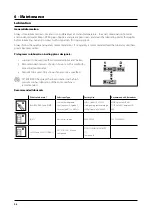

Valves

2. Loosen the 4 head bolts (1).

3. Remove the head (2).

4. Change the valves (3) - note their orientation, so that they are

replaced correctly!

ATTENTION! It is recommended to use new gaskets (4), when

changing or checking the valves.

Diaphragms

5. Loosen the diaphragm bolt (5).

6. Remove the diaphragm washer (6).

7. The diaphragm (7) may then be changed.

8. Check that the drain hole (8) at the bottom of the pump is not

blocked.

9. Apply a small amount of pump grease on the underside of the

diaphragms (between diaphragm and conrod washer).

10. Reassemble the pump with the following torque setting.

• Diaphragm head bolts (1): 90 Nm.

• Diaphragm bolt (5): 90 Nm.

11. Refit the plastic covers (C).

NOTE! The diaphragm bolt on 1000 r.p.m. pumps must be

secured with locking compound.

ATTENTION! Before tightening the 4 bolts for the head (2), the

diaphragm must be positioned between centre and top to

ensure correct sealing between diaphragm pump housing and

diaphragm cover. Turn the crank shaft if necessary.

Re-lubrication after assembly

After disassembling the pump (diaphragm renewal, etc.) the pump

MUST be lubricated with 200 g grease into each lubrication point.

Hardi pump grease cartridge (400g): Item no. 28164600

Overhaul Kit

Pump model: 364 and 464.

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.) can be

ordered. Detect the pump model - the overhaul kit can be ordered by

your local dealer.

Model 364: Item no. 75585900. Model 464: Item no. 75586000.

C

1

3

3

2

4

C

8

4

3

7

6

5

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...