63

5 - Operation

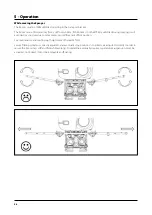

Manifold system

The pressure circuit HLC (Hardi Liquid Circuit) is used with diaphragm

pumps. The HLC distributor has three mechanical valves.

Valve (A) operates the agitator.

Valve (B) activates the powder mixer which flushes powder chemicals

through the tank strainer.

Valve (C) activates the rotating rinsing nozzle for rinsing the main tank

inside when the liquid circuit is rinsed with clean water.

Each function is identified by a pictorial symbol. Valves (A) and (B) are

optional.

Filling liquid chemicals by HARDI TurboFiller (optional)

1. Fill the main tank at least 1/3 with water (unless otherwise

stated on the chemical container label).

2. Turn the Manifold valve towards towards TurboFiller.

3. Set the fan gear lever to neutral position, engage the pump and

set P.T.O. at 540 r/min.

4. Open TurboFiller lid. Measure the correct quantity of chemical

and fill it into the hopper.

5. Engage the hopper transfer device by opening the TurboFiller

suc- tion valve and the chemical is being transferred to the

main tank.

6. Engage the flushing devise to flush the hopper. If powder

chemicals are filled the flushing device must be open before

pouring the powder into the hopper.

7. If the chemical container is empty, it can be rinsed by the

Chemical Container Cleaning device. Place the container over

the multi-hole nozzle and push the upper lever to the left of the

TurboFiller.

8. Close TurboFiller suction valve when the hopper has been

rinsed.

9. Close the TurboFiller lid.

10. Disconnect the pressure to the TuboFiller, keep agitation

activated to ensure homogene concentration.

11. Engage the fan gearbox before spraying.

A

B

C

Содержание ZENIT 400

Страница 2: ......

Страница 4: ......

Страница 10: ...6...

Страница 117: ......

Страница 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...