7

Installation and Maintenance Manual, Compact CA

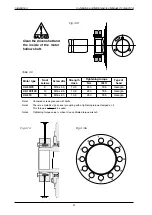

There are three distinct cases:

Case 1:

The motor works in braking mode. Required

charge pressure at the inlet port is according

to diagram below.

Case 2:

The motor works in driving mode only. Required

back pressure at the outlet port corresponds to

30% of value given in diagram below, but may

not be lower than bar (9 psi).

Case 3:

The motor is used with -speed valve. Required

charge pressure at inlet port for valve is

according to AC-3.1 Accessories.

The hydraulic system must be such that the

motor will recieve sufficient charge pres-

sure at the low-pressure port. This app-

lies to all types of installations.

Note:

The diagram is valid for 1 bar (15 psi) case pressure. With increasing case pressure the charge

pressure must be increased accordingly. The graph is valid when 4 ports are used. Max casing

pressure is 3 bar (43,5 psi)(for 1% of the operation time evenly divided, pressure peaks of max 5

seconds upto 8 bar (116 psi) is allowed). Max permitted case pressure at stand-still is 8 bar (116

psi).

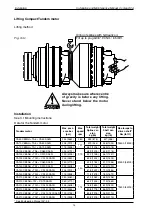

Technical data

2.

TECHNICAL DATA

2.1

Recommended charge

pressure

In hanging load applications, charge

pressure at motors connection must

be according to graph below under

all conditions.

Table 2.1 Charge pressure

RECOMMENDED CHARGE PRESSURE - COMPACT CA MOTORS

Double port connection (4 ports) oil viscolisty 40 cSt / 187 SSU

Compact motors Double port connection (4 ports)

0

2

4

6

8

10

12

14

16

18

20

0

50

100

150

200

250

300

350

400

Speed (rpm)

R

ec

om

m

en

de

d

ch

ar

ge

pr

es

su

re

(b

ar

)

0

50

100

150

200

250

R

ec

om

m

en

de

d

ch

ar

ge

pr

es

su

re

(p

si

)

CA 210

CA 210-180

CA 210-160

CA 140

CA 70,

CA 100,

CA 140-120

CA 50,

CA 70-60

CA 100-80,

CA 140-100

CA 140-80

CA 70-50,

CA 50-40

CA 100-64

CA 50-32

CA 70-40

CA 100-50

CA 50-32

CA 100-40

CA 50-20